- Info CenterHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers of online chlorine analyzers are making bold claims...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

- Cloud

Halogen Amperometric Chlorine Sensors

The Halogen MP5™

Overview

A breakthrough for drinking water and wastewater monitoring, The Halogen MP5™ Multiple Parameter Sensor tests 5 parameters using a 3 electrode amperometric chlorine measurement. The MP5™ is unaffected by flow or pressure, is self-cleaning, automatically compensates for pH, and is certified for NSF-61 use. The MP5™ utilizes Halogen’s patented RapidResponse ORP™ technology, a specialized implementation of ORP measurement that will report more consistent numbers thanks to a high resistance to poisoning.

The MP5™ requires little to no maintenance, can be installed in a flow cell, directly in a pipe, or immersed in a tank, channel, or basin. Simple to install and inexpensive to operate, the Halogen MP5™ is unlike any other sensor on the market today.

Unique Features

- 5 Parameters in a single online near-time analyzer

- Free Chlorine

- pH

- Temperature

- Conductivity

- Rapid Response ORP™*

- Self-cleaning & low-maintenance

- No membranes or electrolyte

- NSF-61: No waste stream required

- Factory calibrated, minimal drift

- Flexible deployment types: directly into a wet tap valve, pvc tees, side stream, or submerged

- The system is equipped with 4 20mA and MODBUS RTU. Other communication protocols are available upon request.

- 24 VDC or 90 to 240 VAC operation

Benefits of the MP5™

Flow Independent Measurement

The sensor is unaffected by flow velocity changes from 0 to 4 m/s. An integrated pump that utilizes a long-lasting, brushless motor delivers a fixed velocity across the electrodes, creating flow independence in any installation. The high-velocity flow across the electrodes improves sensitivity and lowers the Signal to Noise Ratio.

SensiCLĒNE™ Patented Self-Cleaning Technology

A patented electrochemical cleaning method called SensiCLĒNE™ resists polarization and adsorption of organics. Cleaning beads continuously abrade the sensor. This keeps the electrode surfaces, including the pH sensor, free from buildup, scaling, and biofouling. Solid metal electrodes last the life of the system.

These features combine to enable very long intervals between calibration.

No Waste Stream

Because the sensor is approved for NSF-61 usage, it can be installed as a side-stream unit, directly in a pipe, or submerged in a tank with no required waste stream.

Easy to Monitor

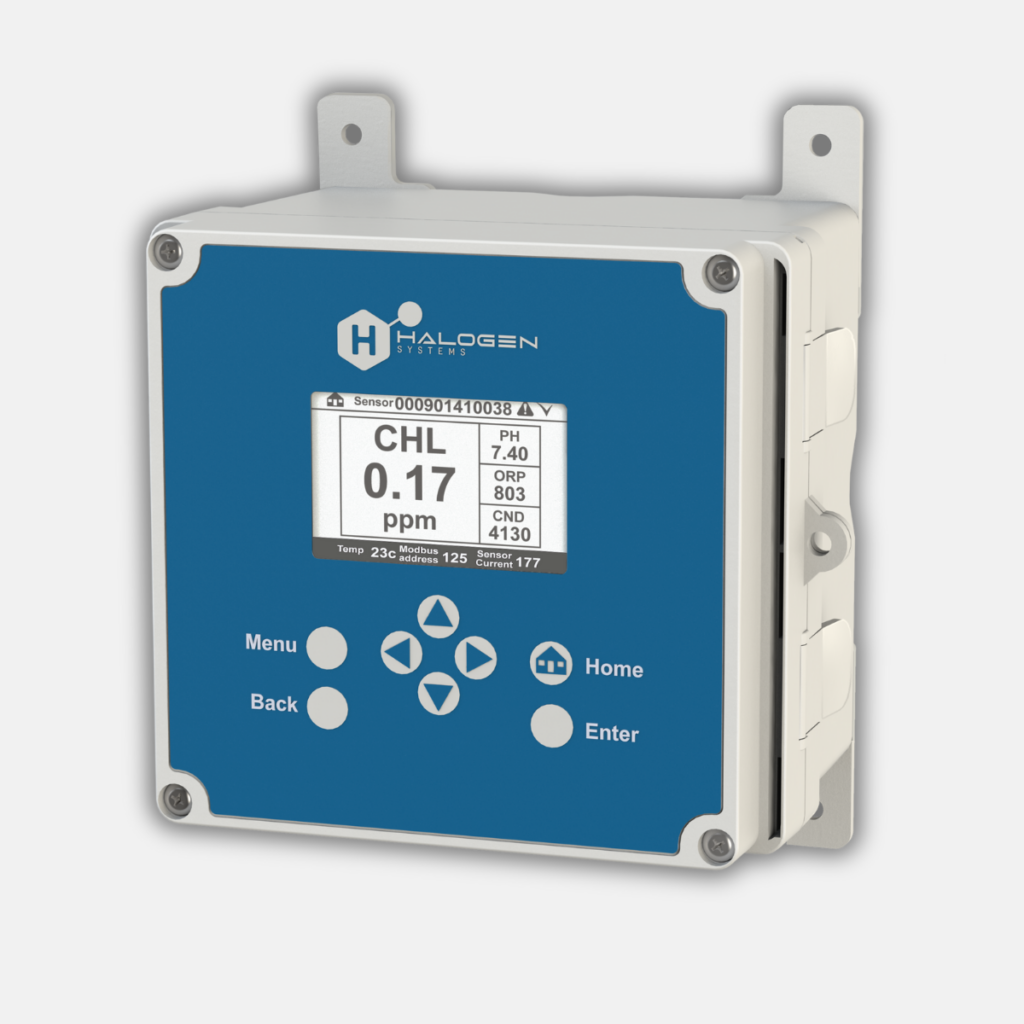

An optional local Display is available for viewing parameters, troubleshooting and calibration of up to 5 separate MP5™ units.

Ease of Service

A Wet Tap installation method enables direct insertion into a distribution pipe. Sidestream, Immersion, and PVC Tee deployments are available. Whatever deplyment, the highly integrated design reduces the electronics cost and size, while increasing reliability.

Models and Deployment Types

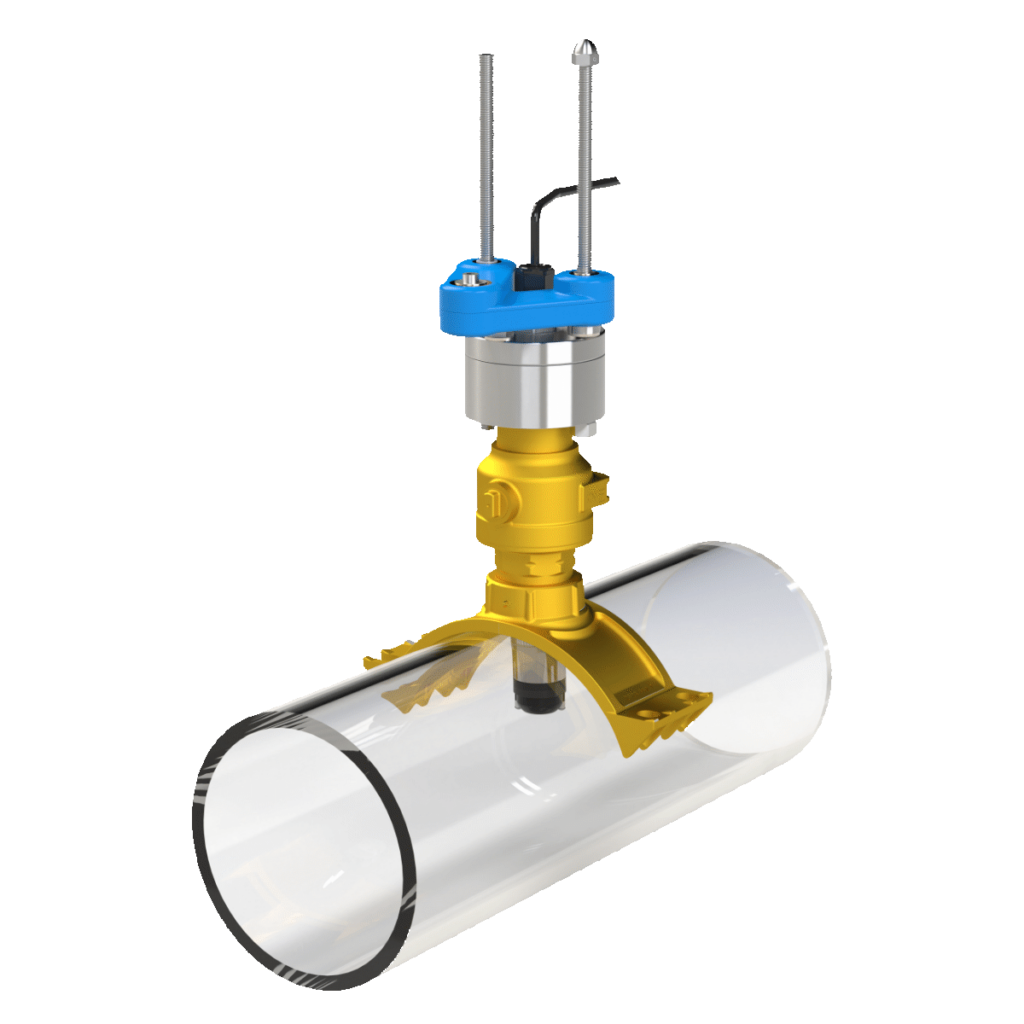

MP5™ H1 Wet Tap (H1WT)

The Wet Tap (or Hot Tap) housing can be deployed as a retractable direct pipe insertion for NSF-61 usage. No-leak retractor options are available.

MP5™ H1 Mid Flange (H1MF-p)

The mid-flange housing (H1MF-P) and the associated 2″ adapter sleeve and collar kit make for an easy sidestream NSF-61 PVC Tee deployment.

H1 Low FLANGE (H1LF-P)

The low-flange model (H1LF-P) can be used to replace existing control-board-mounted setups or used as an NSF-61 submerged in-tank analyzer.

MP5™ Sensors & Specifications

Comparing MP5™ Deployment Specs

Specification | Wet Tap (D-H1WT-P) | PVC Tee (D-H1MF-P) | Sidestream/Immersion (D-H1LF-P) |

|---|---|---|---|

Parameters (5) |

|

|

|

Method | Reagentless, Self-cleaning, 3 electrode, no membrane or electrolyte | Reagentless, Self-cleaning, 3 electrode, no membrane or electrolyte | Reagentless, Self-cleaning, 3 electrode, no membrane or electrolyte |

Measurement Range | 0-10 ppm | 0-10 ppm | 0-10 ppm |

LOD | 30 ppb (0.03 ppm) | 30 ppb (0.03 ppm) | 30 ppb (0.03 ppm) |

LOQ | 90 ppb (.09 ppm) | 90 ppb (.09 ppm) | 90 ppb (.09 ppm) |

Resolution | 0.001 ppm (1 ppb) | 0.001 ppm (1 ppb) | 0.001 ppm (1 ppb) |

Accuracy (FCl) | HSI’s analyzers can be deployed in environments with variable pH and temperature. For specific environments, please contact us. | ||

Turbidity in Sample (no effect) | 3000 ppm (Arizona Test Dust Fine, 50 micron size) | 3000 ppm (Arizona Test Dust Fine, 50 micron size) | 3000 ppm (Arizona Test Dust Fine, 50 micron size) |

Flow Spec | 0 to 4.5 M/Sec (14.7 F/Sec) | 0 to 4.5 M/Sec (14.7 F/Sec) | Bare: 0 to 4.5 M/Sec (14.7 F/Sec) Flowcell: 1 to 30 LPH (0.3 to 8 GPH) |

Water Use | None (NSF-61 models) | None (NSF-61 models) | None (NSF-61 models) |

Pressure Range | -.07 to 10 bar (-10.15 to 147 psi) | -.07 to 10 bar (-10.15 to 147 psi) | -.07 to 10 bar (-10.15 to 147 psi) |

Maintenance Schedule | 1 yr replace SensiCLĒNE™ wear-parts.

Calibration at 3 to 6 mo or as necessary | 1 yr replace SensiCLĒNE™ wear-parts.

Calibration at 3 to 6 mo or as necessary | 1 yr replace SensiCLĒNE™ wear-parts.

Calibration at 3 to 6 mo or as necessary |

Calibration | Factory Calibrated | Factory Calibrated | Factory Calibrated |

Calibration Stability | 6mo (typical) | 6mo (typical) | 6mo (typical) |

Interferances | ClO2, Ozone | ClO2, Ozone | ClO2, Ozone |

* RapidORP™ is HSI’s proprietary indicator for contamination. HSI’s measurement technique and self-cleaning system eliminate poisoning issues, providing a more reliable reading. HSI’s RapidORP™ measurement may have a slight offset from other sensors, it provides a reliable, qualitative measurement that overcomes many of the ORP problems. See the explanatory ORP vs Amperometric Sensors documentation. | |||

Manuals for Drinking Water & Wastewater Applications

Installation Manual

D20 Display/Controller & Sensor for use in Drinking Water and Wastewater applications.

Operating Manual

MP5 Online Chlorine Analyzer Manual (2024.06.12-v4.02) for use in Drinking Water and Wastewater applications.

Installation Manual

Installation Manual for MP5™ D-H1WT-P chlorine analyzer in Wet Tap deployment with remover tool

Installation Manual

Download the Wear Parts Replacement manual for the SensiCLĒNE™ self-cleaning technology in MP5™ Analyzers

MP5™ SOLUTIONS AND KITS

Kit with flow-cell deployment (MKIT) and display controller along with a wall mounting plate, provides a drop-in upfit sensor replacement.

Battery power and remote telemetry for an MP5™ deployment. Use for outer grid monitoring, dead-ends, or other remote implementations.

Leverage the dependability and low maintenance of the MP5™ for remote tank monitoring with battery power and remote telemetry.

Retractable remover kit for MP5™ wet-tap analyzer (H1WT-P) in water pipes allows for maintenance without interrupting flows.

This deployment uses a water-proofed low-flange MP5™ (H1LF-P), a sourced boom and harness, or can simply be placed in a tank or trough.

Combine a mid-flange MP5™ (H1MF-P) with an adapter sleeve—in PVC or Stainless steel—sized for deployments in a 2″ PVC tee.

Fits low-flange MP5™ (H1LF-P) and adapts for side stream and control board usage based on which flow cell type is ordered.

Both 24V DC (DC20-L) and 120-240V AC (DC20-H) versions feature (4) 4-20 mA analog outputs, and an M-12 Connector, 3 relays, SD card.