- Info CenterHalogen MP5 More Accurate Than Hach CL10 - San Jose Water The Report Details Background San Jose Water...Halogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

Thank you to all the attendees who visited us at WEFTEC 2023! We enjoyed previewing our new D20 display controller for our Online Chlorine Analyzers, and have even more exciting news coming soon.

Chloramine

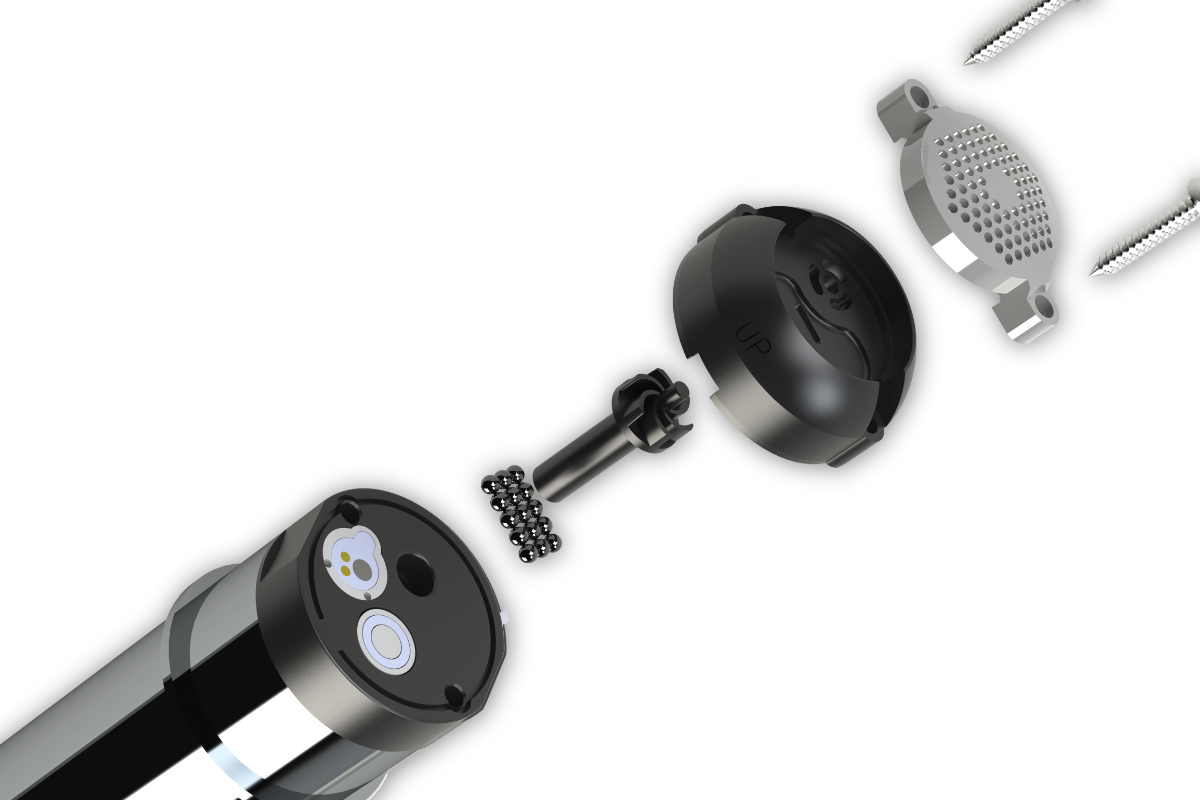

BREAKTHROUGH TECH. THE MP6™

Measuring 6 parameters:

• Monochloramine

•Free chlorine

• ORP • pH

• Conductivity • Temp

D20

D20 CONTROLLER

Standard Features:

• SD Card data logging

• Easy Calibration (pH & Cl)

• IP65 Rating

• Four, 4-20mA Outputs

• Dry Contact Alarm

• Two-Relay Output Switches

Save Money

Self-Cleaning

Extreme Virsatility

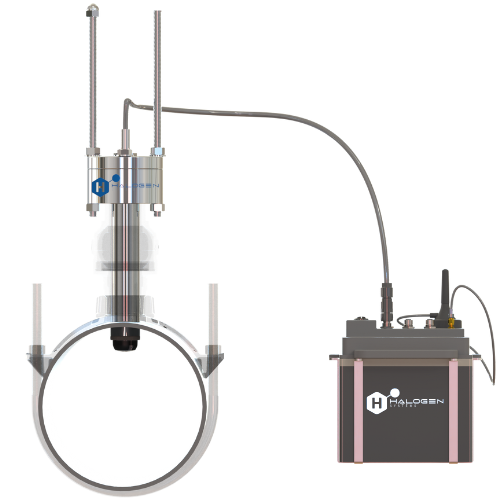

Wet Tap

WET TAP REMOVAL PROCESS

Founded in 2013, Halogen Systems, Inc. specializes in using chlorine sensors to solve challenging problems in water monitoring. Proven in the tough environment of Ballast Water Management Systems for ocean-going shipping vessels, Halogen’s patented technology uses no membranes, no reagents, and is impervious to changes in flow or pressure. Our amperometric chlorine analyzer is well suited for nearly any water testing need, especially detecting residual free chlorine in Drinking Water, and can be used in a wide variety of installation types, from direct-pipe insertions, to side-stream testing boards, or even submerged in tanks.

Water conservation is paramount in being good stewards of our environment, and municipal water facilities constantly seek ways to conserve water. One effective measure is eliminating waste streams while capturing readings for chlorine residual. By installing Halogen Systems Inc.’s MP5, hundreds of water facilities save an impressive 70,000 gallons of water annually per sensor. This is the equivalent volume of three standard-sized swimming pools. [Find Out More]

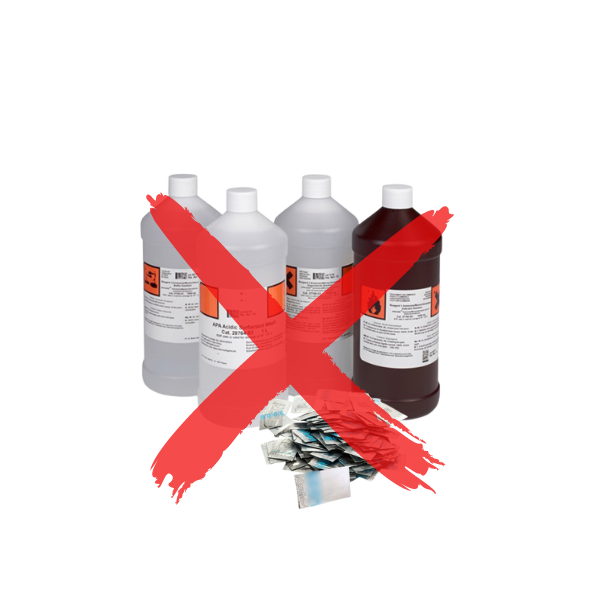

By eliminating the need for reagents, tubing kits, and membranes, users stand to save an estimated $1000 annually per sensor. This financial efficiency not only reduces overhead but also underscores the economic advantages of our technology. With less recurring costs contributes to a more sustainable and economically viable solution, making it a prudent choice for those seeking operational efficiency and financial responsibility. [Find Out More]

By eliminating the need for reagents, tubing kits, and membranes, users stand to save an estimated $1000 annually per sensor. This financial efficiency not only reduces overhead but also underscores the economic advantages of our technology. The absence of these recurring costs contributes to a more sustainable and economically viable solution, making it a prudent choice for those seeking operational efficiency and financial responsibility. [Find Out More]

Play Video

Ballast Water Management Systems (BWMS) designers appreciate the reliability, accuracy, and flexibility they get from a system using Halogen’s TRO sensors. As with all Halogen sensors, the TRO needs no reagents or membranes and is unaffected by flow or pressure. In addition, Halogen TRO calibrations last for months. Truly, the TRO family is the perfect fit for the difficult operating environment of BWMS. [Find Out More]

Based on technology developed for testing Ballast Water Management Systems in Ocean-going Shipping Vessels, Halogen’s MP5™ is well suited for the difficult environments of Wastewater Treatment and Reclamation. With no membranes or reagents to replace and retaining calibration for months, the MP5™ is a simple choice for many engineers and plant operators who value long-term accuracy, durability, and reliability. [Find Out More]

Request a demo and experience how much time and frustration you will avoid. Fill out the form, and we will be in touch!