- Info CenterHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers of online chlorine analyzers are making bold claims...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

MP5™ Municipal Drinking Water Amperometric Chlorine Sensor

NSF-61 & MP5™: Zero Water Waste Drinking Water Testing

For decades, Drinking Water plants have been pouring hundreds of thousands of gallons of treated water down the drain just for testing. Halogen’s MP5™ solves this problem.

Certified for NSF-61 installations, Halogen’s MP5™ sensor measures 5 testing parameters in one online unit but won’t cost a drop of treated water. The NSF-61 certification and patented built-in impeller allow a plant great flexibility in installation. Flow-independent, self-cleaning, and needing no waste stream, it can be inserted directly into a drinking water pipe, suspended in a trough, or simply dropped into a tank.

Plant operators that use Halogen’s MP5™ in their workflows can’t stop talking about the savings they see. Not only are they saving water (a mission-critical result in many areas) they greatly reduce their costs. With no reagents or membranes to buy and replace, no flow-control plumbing to install or maintain, no waste stream to manage, and calibrations that are stable for months, a plant reduces overhead and can assign personnel to other critical tasks.

Measure Five Parameters in One Online Chlorine Analyzer

Track the important parameters

The NSF-61 certified, Halogen MP5™ analyzer measures 5 testing parameters in near-time using one online unit without losing a drop of treated water. Operators can assess free chlorine, pH, temperature, conductivity, and oxidation-reduction potential (ORP) in near-time in the pipe with no waste stream.

UNAFFECTED by flow or pressure

The MP5™ adapts to nearly any flow or pressure. Even a dry pipe won’t ruin the calibration. It can be installed directly in a pipe, located side-stream, suspended in a trough, or simply dropped in a tank. Whatever the deployment type or parameters, the MP5™ is unique in accuracy, reliability, and stability.

Add Simplicity to the Workflow

The MP5™ makes things simple. Our NSF-61 certification means no flow-control plumbing and no waste stream to mitigate. There are no reagents or membranes to stock, manage, or replace. Instead, you’ll replace the cap, cleaning beads, and impeller blade once per year in 5 minutes without affecting the calibration.

The MP5™ ROI Calc: Lower Operating Cost + Minimal Maintenance + Zero Water Waste

How Much Water Are You Losing?

Old-tech membrane-and-reagent sensors can require around 69,000 gallons of flow per year. In areas subject to water restrictions, that is a bitter pill to swallow (need water for that?), but even in areas where water is plentiful, the treatment costs and maintenance headaches create entrenched losses.

The MP5™ Makes Remote Tanks Easy

Installed directly in-pipe and unaffected by flow and pressure —even a dry pipe won’t throw off the calibration— the MP5™ is a dream for operators with remote tanks. Combined with our upcoming solar-powered cell-modem reporting solution for the ultimate remote tank sensor solution.

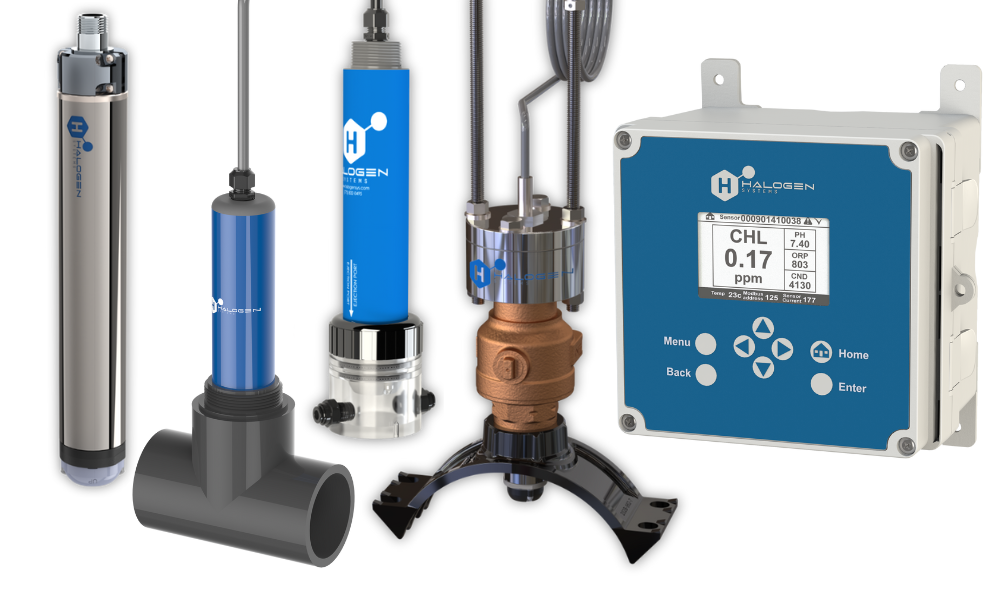

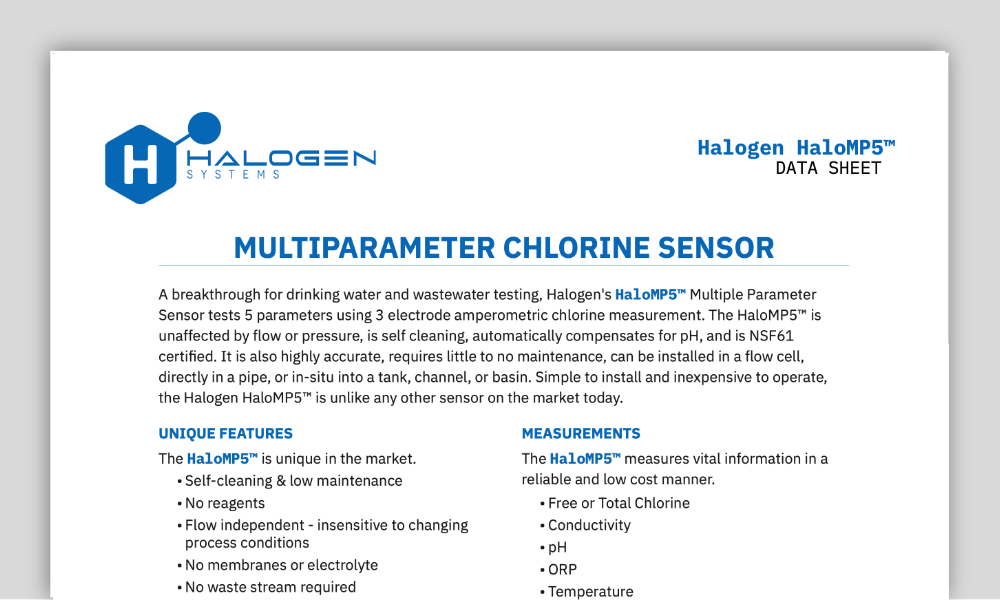

MP5™ Data Sheet

Amperometric Sensors With Patented Technology to Modernize Your Testing

Add Accuracy and Simplicity While Lowering Your Maintenance Costs

Plant operators know exactly how much money gets spent on membranes, reagents and electrolyte. What might be less clear is how much time the team spends on maintenance and subsequent calibrations on existing old-tech sensors. Those man-hours add up fast. In contrast, the MP5™ arrives factory-calibrated and stabilizes within 5 minutes of installation. Not only are there no membranes, reagents or electrolyte, there’s no monthly maintenance. Plants have seen calibrations last many months. That sort of simplicity goes straight to the bottom line.

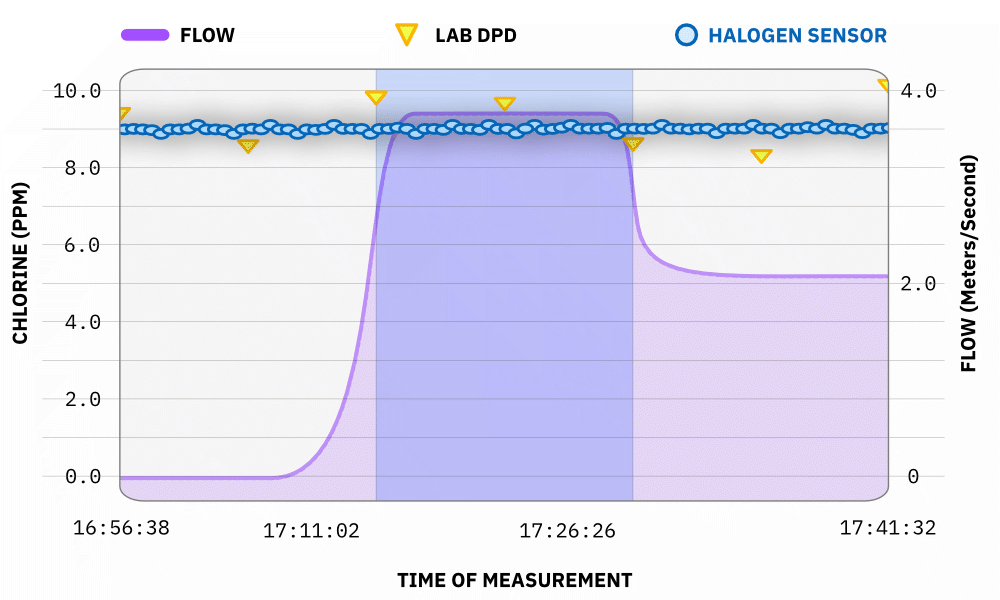

Orange Co, Florida Pilot Program Results

The operators and staff in this program were pleasantly surprised at just how little maintenance has been needed. “Sensor calibration is performed initially and has not been required in over six months…manpower savings are … an estimated savings of 2,080 man-hours per year for five sensors.” <read more>

Technology forged in the harshest environments. Now ready for yours.

With patented tech created to solve the environmental impact issues dogging the maritime shipping industry, Halogen has created a solution that solves problems many wastewater plant operators had written off as “the way things are”. The Halogen MP5™ is designed to let those same operators work within a new paradigm.