MP5™ Success Story – Orange County Florida

Successful Remote Monitoring Test Using Cellular Telemetry Option

PILOT PROGRAM: ORANGE COUNTY, FLORIDA (OCFL) The Orange County Utilities water system provides reliable service to a growing number of customers in Orange County. In 2021, the utility’s four regional water facilities and eight remote facilities produced 24.2 billion gallons of water for its 451-square-mile service area. In August of that year, they began a pilot program for the Halogen MP5. Preliminary results were reported at an American Water Works Association conference in the third quarter of 2022. At that time, Orange County Utilities began adding to the five sensors initially deployed during the pilot. We greatly appreciate the opportunity as well as the thoroughness and professionalism of their staff. Their report follows, edited only for formatting.

The Report from Orange County, Florida (OCFL)

Background

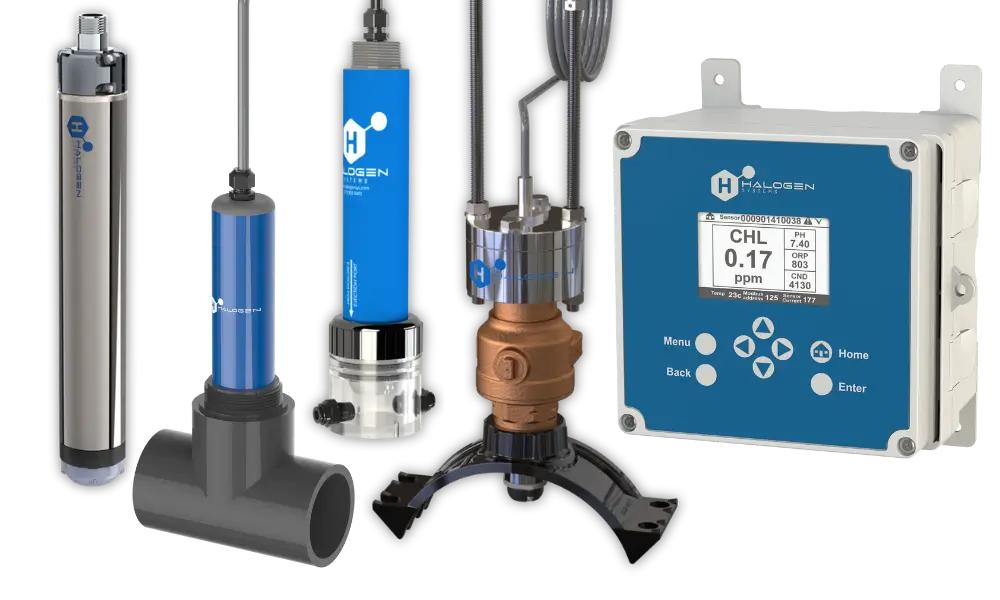

Orange County Utilities draws groundwater from the Floridan Aquifer. In August 2021, the Orange County Utilities Field Services Division began testing a new multiparameter sensor (Halogen MP5) for use in its distribution and transmission system. A cellular monitoring system that collects data every minute and transmits it every two hours for 24/7 monitoring was deployed along with the sensor. The sensor collects pH, chlorine, and water temperature via 4-20 milliamp outputs and a separate pressure transducer.

The pilot began with what was believed would be the most challenging application: the East System.

To neutralize hydrogen sulfide in the East System, raw water is treated with carbon dioxide for pH adjustment to make the hydrogen sulfide more soluble to be stripped by force draft aeration. After hydrogen sulfide is stripped, chlorination takes place. Following are the results of the first trial:

- One Halogen MP5 sensor was installed December 7, 2021.

- Staff expected to have to clean the sensor with a diluted acid solution, but they have not had to do this since operation began over a year ago.

- Since the site does not have power available, staff set up two marine batteries in a vault to supply power for extended periods. This, however, requires monthly trips to swap out batteries with a fully charged set. Obviously, this is not an ideal long-term setup, so solar is being explored.

Based on the success of the first trial, two more sites were added to assess sensor performance and functionality under other treatment processes utilized. So far, the results have been good with no major issues:

- The West System uses chlorination alone (sodium hypochlorite) for both disinfection and to help oxidize the hydrogen sulfide. Due to this, a bit of chalky powder (sulfur buildup) is present at times. Two Halogen MP5 sensors were installed on this system: the first on March 24, 2022, and the second on July 27, 2022.

- Sensor performance was good under these conditions as well.

- With this success, two additional sensors were deployed August 15, 2022, on the South West System, which uses ozone and subsequent chlorination for water treatment.

The Halogen MP5 sensor performed extremely well at all the sites. While the manufacturer states accuracy of ±15%, in this experience the sensor has performed in a much tighter range, often within 5% or less.

Orange County Utilities currently has a total of five sensors and is continuing to add sensors in its transmission and distribution lines.

According to the manufacturer, a solar/battery combination that works with a new model of their sensor is available. The small and easily deployed 18-watt package is expected to eliminate batteries and battery recharging cycles, opening up more sites for monitoring that are not currently practical.

Results/Conclusions So Far

- Reduced manpower requirements – As everyone is aware, manpower is in short supply in most areas of the country. Truck rolls to pull daily or weekly grab samples have largely been eliminated. Periodic calibration checks are made to ensure the accuracy of the data collected. Staff was pleasantly surprised that the calibration requirements of the sensor are minimal. Sensor calibration is performed initially and has not been required in over six months. The manpower savings are roughly two hours per day per sensor, with an estimated savings of 2,080 man-hours per year for five sensors.

- Since the sensor works under almost any flow condition and does not require reagents, its operating cost is quite low and limited to replacement of some wear parts.

- With the combination of cellular modes and MP5 sensors, there is better access to data with readings every minute.

- The sensor is very useful in dead ends. Auto flusher times are monitored to ensure they are frequent enough and long enough to keep the mains properly chlorinated. This helps to make operations more efficient as well as cost productive and labor saving.

- These sensors have also been used on two different water sources that are later combined into a single distribution line, assisting staff in identifying which water source is the cause of the problem or anomaly.

- Ease of use is the most important feature. Once the sensor is set up and calibrated, staff gets the readings both locally at the sensor’s display as well as remotely on the cellular IIOT device, making further investigations and troubleshooting easier and more streamlined.

- Halogen Systems has outstanding customer service. During the research and development phase, they were willing to help in every way possible and promptly resolved issues. Their employees are very professional and friendly.

Learn More

See more about the technology.

More info about Remote Monitoring Solutions

Find out more about the MP5™ Remote Monitoring Solution or contact a rep.

Have Questions? Get Answers.

If the technologies and benefits listed above raise any questions, you may find the answer you’re looking for in the FAQ or Technologies pages.

Our contact page also allows you to reach out with a specific question and we’ll get back to you as quickly as possible.

Latest Blog

Offshore Windfarms Benefit Form Halogen System Inc.’s Chlorine Analyzer Technology

Air Travel & Potable Water Problems – Our Chlorine Analyzer Can Help