- Info CenterHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers of online chlorine analyzers are making bold claims...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

- Cloud

Potable Water Chlorine Monitoring

Solutions for Cruise Ships

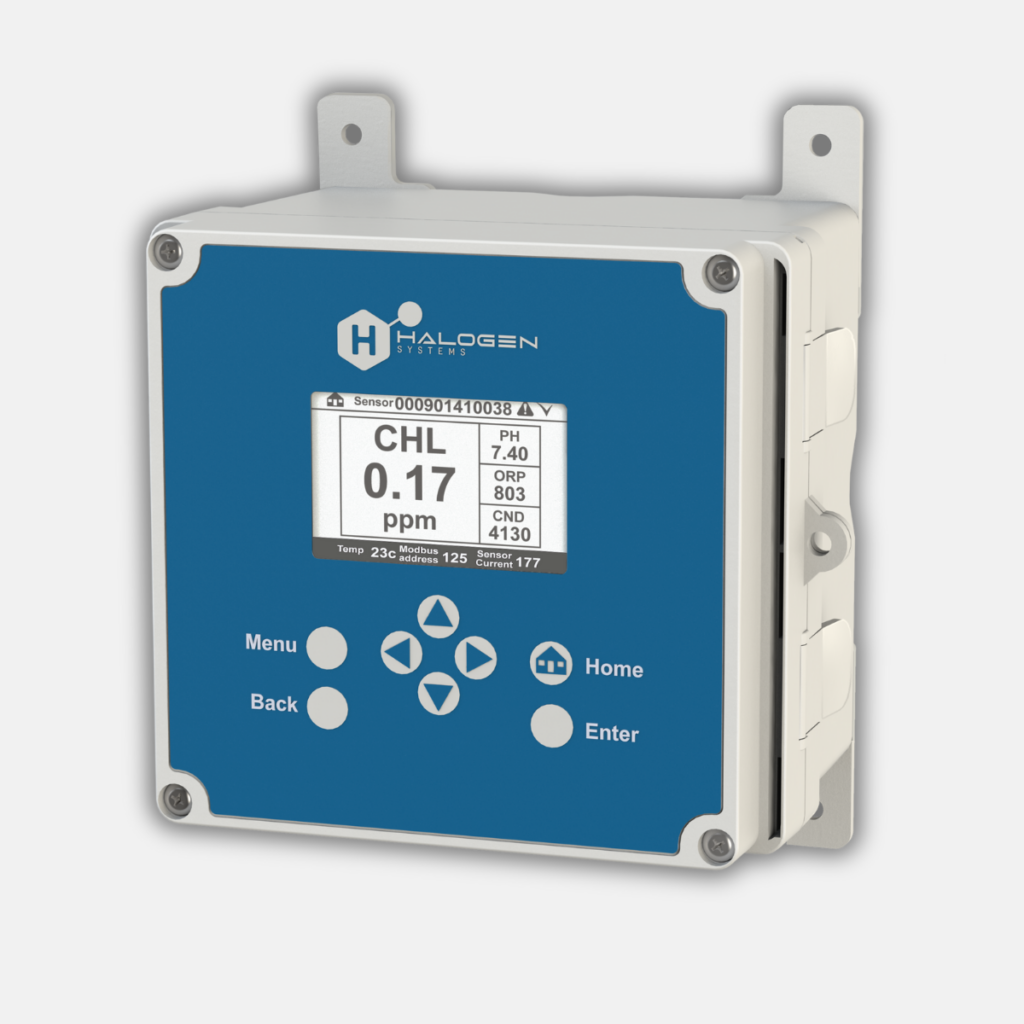

The Halogen MP5™: Robust, Accurate, and Stable.

Protect against Legionella and other bacterial contaminations with compact low-maintenance potable water chlorine monitoring solution based on the Halogen MP5™.

Legionella is a dangerous and hard-to-kill pathogen that is better to mitigate before it gets a foothold. Consistent monitoring of onboard water is imperative. However, the nature of the cruise industry makes consistency difficult. Most chlorine sensor solutions are either highly manual or maintenance-heavy and temperamental. DPD and old-tech amperometric sensors require consistent flows with no bumps in pressure or vibrations, which makes them ill-suited for cruise-ship use.

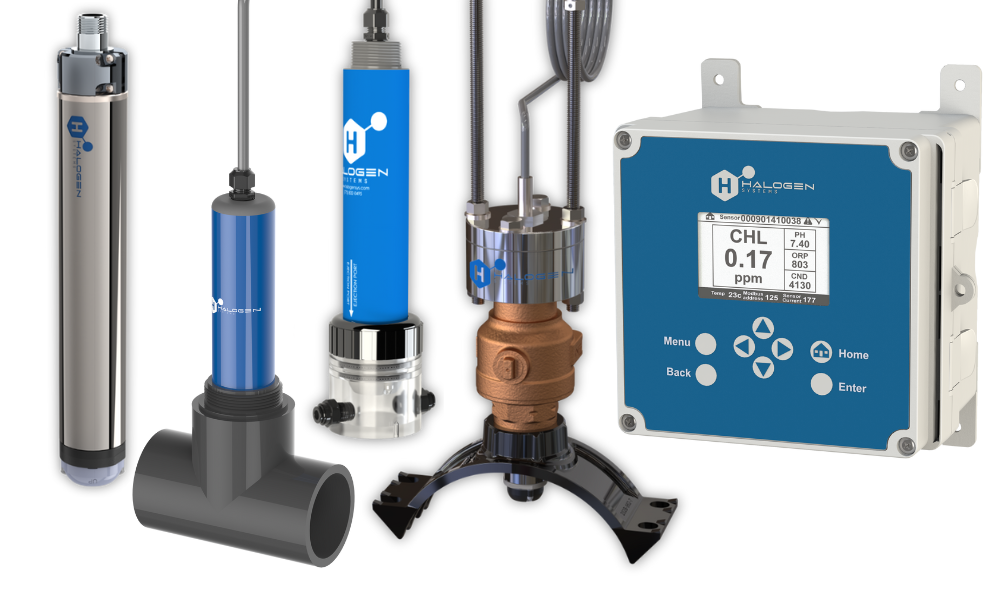

The Halogen MP5™ is a good choice for solutions aimed at solving the issues around cruise ship water monitoring. The technology was proven in the harsh environment of ballast water systems for ocean-going cargo ships. It is unaffected by flow or pressure and is certified for use in NSF-61 applications. The MP5™ can be installed directly in the circulation pipes or submerged in holding tanks. Side-stream deployments can be used to test source water before it is added to holding tanks.

Halogen is working with partners to create options for ship owners. Contact us for more information.

Solve Cruise Potable Water Monitoring Problems with the MP5™

Multiple Parameters, one unit

To keep ships out of the Legionella-cultivating zone, the MP5™ measures Free Chlorine, pH, Temperature, Conductivity, and RapidResponse ORP in one compact online unit. It arrives factory calibrated and maintains calibration for months.

Online & Remote Monitoring

Halogen’s MP5™ can be deployed in-pipe, in PVC Tees, or submerged in holding tanks, while the display and controller unit can be mounted in the control room. A new cellular-enabled controller will post telemetry data at specified intervals directly into monitoring workflows.

Near-time Reporting

The MP5™ can be set for constant monitoring and can run for months with minimal interaction so operators can know what they need to know in near-time . Reports can be collected and sent in batches or simply streamed for up-to-the-minute data.

Amperometric Sensors With Patented Technology to Modernize Your Testing

Bare Electrode Sensor

Amperometric Sensors have many advantages over the older membrane and reagent technology. Halogen’s implementation of bare 3-electrode amperometric technology provides pH-stabilized precise measurements of Free Chlorine without introducing additional complexity to your workflow.

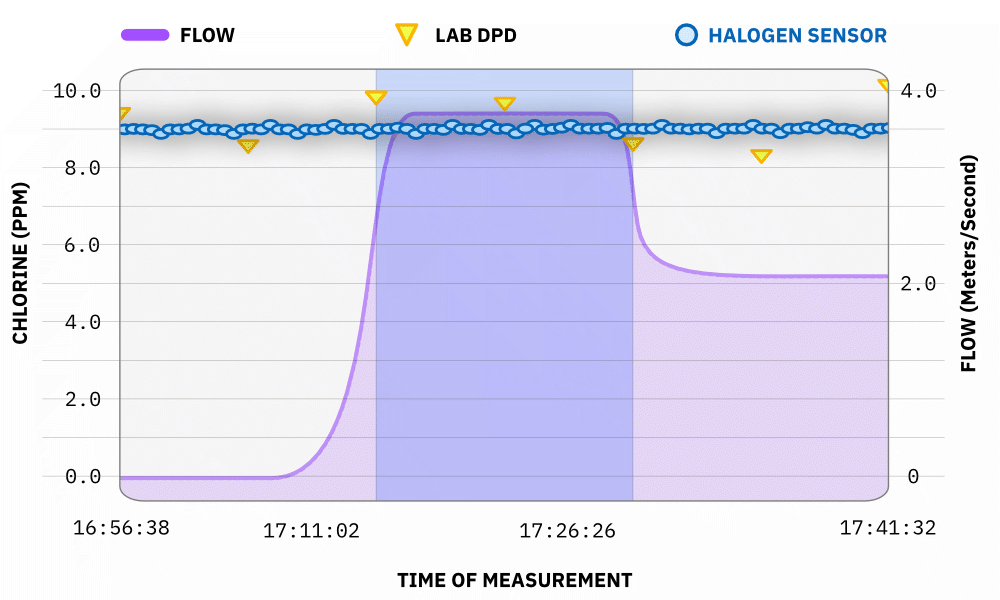

Self Cleaning

The old amperometric technology used by competitor sensors still requires a membrane and electrolyte to guard against sensor fouling. Such membranes are sensitive to flow and pressure spikes. Halogen’s patented SensiCLĒNE™ technology prevents fouling without introducing pressure or flow sensitivity.

MP5™ SOLUTIONS AND KITS

Kit with flow-cell deployment (MKIT) and display controller along with a wall mounting plate, provides a drop-in upfit sensor replacement.

Battery power and remote telemetry for an MP5™ deployment. Use for outer grid monitoring, dead-ends, or other remote implementations.

Leverage the dependability and low maintenance of the MP5™ for remote tank monitoring with battery power and remote telemetry.

Retractable remover kit for MP5™ wet-tap analyzer (H1WT-P) in water pipes allows for maintenance without interrupting flows.

This deployment uses a water-proofed low-flange MP5™ (H1LF-P), a sourced boom and harness, or can simply be placed in a tank or trough.

Combine a mid-flange MP5™ (H1MF-P) with an adapter sleeve—in PVC or Stainless steel—sized for deployments in a 2″ PVC tee.

Fits low-flange MP5™ (H1LF-P) and adapts for side stream and control board usage based on which flow cell type is ordered.

Both 24V DC (DC20-L) and 120-240V AC (DC20-H) versions feature (4) 4-20 mA analog outputs, and an M-12 Connector, 3 relays, SD card.

Have Questions? Get Answers.

If the technologies and benefits listed above raise any questions, you may find the answer you’re looking for in the FAQ or Technologies pages.

Our contact page also allows you to reach out with a specific question and we’ll get back to you as quickly as possible.