- Info CenterHalogen MP5 More Accurate Than Hach CL10 - San Jose Water The Report Details Background San Jose Water...Halogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

Amperometric Technology Benefits

Halogen’s unique implementation of three-electrode amperometric technology resists fouling maintains calibration and enables true NSF-61 implementation for drinking water monitoring with no waste stream required.

“Amperometric technology allows for Chlorine monitoring in more conditions with a lower TCO. Halogen’s implementation sets a new bar for amperometric sensors with the MP5™, a Chlorine analyzer approved for NSF-61 use in drinking water pipes with no required waste stream.” — Michael Silveri, CEO

How Does an Amperometric Sensor Work?

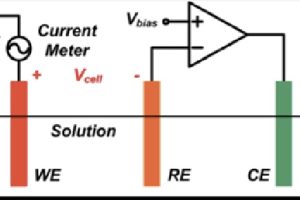

All amperometric chlorine sensors are electrochemical devices that rely on this reaction to measure chlorine: Electrons flow from the reduction of Hypochlorous acid to chloride at the cathode. This electron flow is measured by the sensor. There are two basic designs: Bare and Membrane. In a Bare Electrode system, the three-electrode Amperometric Measurement Method (See diagram 1) is used. Voltage is applied between two electrodes using a potentiostat that compensates for solution resistance. The measured current is proportional to the chlorine level.

In a Membrane Style system, the two-electrode method is used. It is essentially the same as the three-electrode method, however, the Counter Electrodes and the Reference Electrode are combined and separated from the solution by a membrane. Electrolyte slowly diffuses into the solution and must be replenished periodically. Amperometric sensors are free from many interferences like manganese, iron, and nitrate; substances that interfere with colorimetric methods.

Find more information about the Amperometric Chlorine Measurement in a WE&T article by Michael Silveri, founder of Halogen Systems, Inc.

Halogen's Unique Technology: Amperometric Improved

Flow independent, No Water Waste

Changes in flow and pressure can cause fluctuations in the level of chlorine passing through the membrane. These changes, in turn, will affect the reading. All existing amperometric sensors need constant flow, usually by using a waste stream, to maintain their accuracy and calibration. Water consumption by water treatment sensors is often overlooked. Unless a sensor is certified to NSF61, the water that touches the sensor cannot be put back into a potable water tank. One drinking water utility estimated water usage of 14.7 million L/yr (3.8 million gal/yr) for eight of its facilities when using conventional amperometric sensors — just to measure chlorine.

Halogen’s MP5™ analyzer uses a built-in impeller to generate a consistent flow across the 3-electrode array as well as the pH sensor. Not only is it unaffected by flow or pressure, but the MP5™ is also the only amperometric sensor approved for NSF-61 use in drinking water pipes (or reservoir tanks) with no required waste stream.

Typical Treated Water Waste

pH Calibration Reading

Stable Calibrations Despite Changes in Temperature or pH

Temperature fluctuations cause non-linear signal changes in old-tech sensors due to membrane characteristics, resulting in a loss of calibration. A treatment plant in the City of Lakewood, CA, relayed that frequent (weekly or semiweekly) calibration is necessary for the Amperometric Chlorine sensors they have used in the past. The MP5™ operates within a range of 0 to 100° C, and maintains calibration in environments where old-tech sensors become maintenance-intensive.

All amperometric sensors are affected by pH changes in the process. pH measurement will usually improve the chlorine measurement accuracy. pH measurement does introduce another calibration and maintenance requirements which is a critical issue. The MP5™ chlorine analyzer uses a specially developed integrated pH sensor with a long life that will not be damaged even when left dry for weeks or even months in ballast pipes. These sensors also are cleaned by the sensor’s self-cleaning system.

Patented Self-Cleaning System

Competitor amperometric sensors protect their bare electrodes from fouling and drift using a membrane, behind which is an electrolyte solution. While this solves the fouling problem (and eliminates the need for a reagent) the membrane itself cannot be cleaned automatically. Replacing the membrane will require a new calibration which can take 6 hours to stabilize. Halogen’s self-cleaning technology —proven in seawater chlorine monitoring— allows for the benefits of bare electrodes without the downsides of membranes or electrolyte. It arrives factory calibrated, stabilizes in minutes, and maintains calibration much longer than competitive units.

Halogen’s patented SensiCLĒNE™ technology keeps the electrodes and pH sensor free of build up. An electrochemical cleaning method resists polarization and adsorption of organics. while integrated cleaning beads continuously clean the sensor, keeping the electrode surfaces, including the pH sensor, free from the buildup of hardness and biofouling. The solid metal electrodes last the life of the system.

SensiCLĒNE™ Beads Render

Many Applications Benefit from a Self-Cleaning, Low-Maintenance Analyzer

Halogen’s technology helps maintain stable calibrations while lowering maintenance requirements. This combination makes MP5™ a good option for monitoring stations that might otherwise involve constant crew rollouts for operator interventions. When packaged with remote telemetry options, the MP5™ can be the foundation for IoT monitoring solutions. See below for example applications.

REMOTE RESERVOIR MONITORING

Suspended directly in the tank at whatever level is needed, an MP5™ will report to the controller display, or via a cellular telemetry reporting option. When running on an optional battery kit, the MP5™ can sample at predefined intervals and operates with no maintenance interaction for a month.

END-OF-LINE TESTING

Municipalities that currently have to roll a truck to know with certainty that homes at the end of the line are getting appropriate PPM can lower costs and increase accuracy by putting an MP5™ directly in the neighborhood water pipe. Data can be cached on the display or broadcast via cellular telemetry.

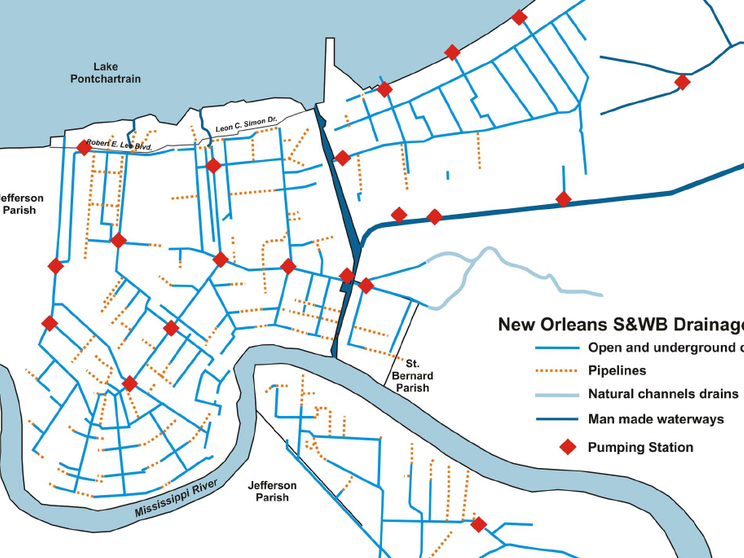

PINPOINT GRID MONITORING

Water-aging and other chlorine wastage issues in a water grid can be discerned by deploying MP5™ analyzers at desired points in the system. Operators can track temperature, conductivity, pH, and even ORP no matter the flow or pressure (up to 10.5 bar) via remote telemetry options.

CRUISE SHIP DRINKING WATER

To guard against Legionella, cruise lines need to monitor chlorine levels in their freshwater tanks, guard against contamination from source providers, and sample at the actual taps. SensiCLĒNE™ technology and the flexible installation options of the MP5™ analyzer allow operators to create solutions that will work in this tough environment.

AIRLINE WATER TANKER MONITORING

Studies in the UK show water tankers as a source of contamination in airline drinking water, but monitoring these mobile refill units is a highly manual process, making consistency difficult in a rushed environment. Self-cleaning, durable, and flow-independent, the MP5™ can be the foundation of an source-side solution.

EWR MONITORING

Environmental Water Reclamation (EWR) is a hot topic in areas that are facing water shortages, but remote holding tanks can also become hot spots for all sorts of bacterial growth. Thanks in part to SensiCLĒNE™, the MP5™ is unaffected by flow and turbidity, making it a good choice to build a robust, low-maintenance monitoring system.

Have Questions? Get Answers.

If the technologies and benefits listed above raise any questions, you may find the answer you’re looking for in the FAQ or Technologies pages.

Our contact page also allows you to reach out with a specific question and we’ll get back to you as quickly as possible.