- Info CenterHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers of online chlorine analyzers are making bold claims...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

- Cloud

Traditional DPD vs. HSI's™ Amperometric Chlorine Sensor

DPD Online Instruments VS.HSI's Amperometric Chlorine Sensor

Ballast Water Treatment Systems (BWTS) for larger ships use residual oxidant systems to inactivate invasive aquatic species. In both cases, the residual oxidant is bromine.

Sensors or analyzers are used in tandem to control the level of oxidant generated during ballasting by detecting the residual oxidant levels before deballasting (ballast water pumped out) operations occur. During ballasting, water is loaded, treated, and monitored to ensure the inactivation of invasive species is complete. During deballasting, sensors monitor the residual oxidant level to ensure that the residual concentration is below 0.2 (0.1 in some cases) ppm as required by International Maritime Organization and the US Coast Guard.

Most BWTS systems use N, N-diethyl-p-phenylenediamine, (DPD) Instrumentation at various locations onboard the ship. These units use regent feed colorimeters to indicate Total Oxidant levels. They require a relatively long cycle time of 75 seconds before displaying a reading. In addition to the cycle time, discarding the first or second measurement is typical due to initial inaccuracies. This delay gets compounded when the sample water must flow hundreds of feet to the colorimeter location before analysis can occur on larger ships. Sampling pumps, water lines, and automated valves are also necessary, increasing CAPEX costs.

While no analytical method is perfect, traditional DPD has several limitations in this application. They require:

- Use of tubing as small as 1mm (ID) (which tends to clog via dried reagents or biofouling)

- Filtration of the sample (Increase turbidity causes inaccuracies)

- Filter cleaning

- Cleaning of the colorimeter with acid every 60 days

- Regent replacement every 60 days

- Disposal of a waste stream

Conclusions:

In general, these systems are complicated. They can be hard to troubleshoot and require considerable maintenance. For a limited-size crew, this can prove problematic as there are many duties during ballasting and deballasting.

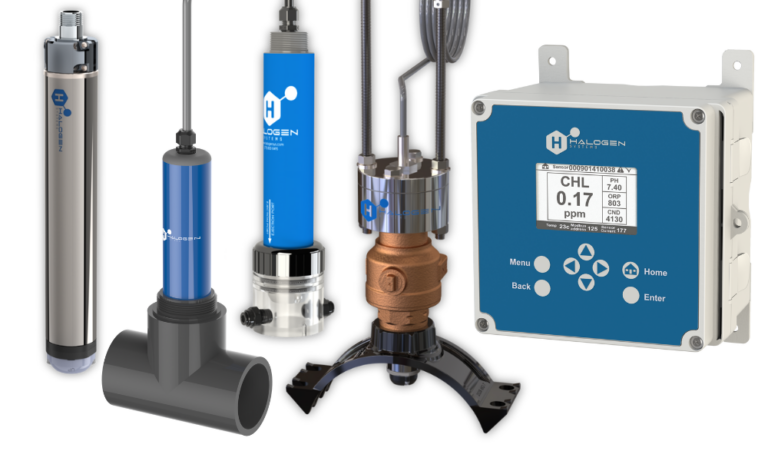

Halogen Systems, Inc. manufactures sensors for seawater, drinking water, swimming pools, and cooling towers. Its Oxidant/ Deoxidant Sensor for use in Ballast Water Treatment Systems is designed for ships. The sensor is installed directly in the ballast pipe and measures TRO every 50 seconds and is accurate within two and at times one cycle.

The advantages of the HSI Sensor:

- Long intervals between calibrations

- Self-cleaning electrodes

- Flow independent measurement

- Direct pipe insertion

- Integrated salinity measurement

- Auto-ranging oxidant measurement from 0.07 ppm to 15 ppm

- No electrolytes or membranes

- Biofouling resistant

Conclusions:

HSI’s chlorine sensor (TRO sensor) is designed for this challenging application. It is a solution that will save both OPEX and CAPEX costs and simplify operations.

Learn More:

- Amperometric Free Chlorine Monitoring– Our patented sensor measures free chlorine every 55 seconds. The readings are pH, temperature and conductivity compensated.

- Integrated pH sensor: The MP-5 has a two-year life expectancy versus the industry average of six months. Our sensor cartridge is an integral part of the sensor. Because of this, we designed our chlorine sensor so that it self-cleans continuously. We use a unique pH sensor that tolerates pressures up to 150 PSI. The pH sensor is shipped dry, wets out within minutes, and does not need frequent calibration.

- Integrated Conductivity Sensor: Changes in water conductivity is an integral way for water utilities to determine water quality. These shifts can indicate contamination, a pollution event, or other problems.

- Oxidation-Reduction Potential (ORP): Measuring ORP in drinking water is another indicator of possible contamination or pipe failure. Our chlorine sensor has a unique method of measuring ORP and keeps the electrodes clean.