- Info CenterHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers of online chlorine analyzers are making bold claims...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

DPD vs. Amperometric Sensors

Online Reagent Feed (DPD)

There are two available methods for Total Residual Oxidant (TRO) measurement: Oxidation Reduction Potential (ORP) sensor and amperometric sensor. Until now, there have been no amperometric sensors that have been practical in a ballast water application. This paper will examine the relative benefits and limitations of both methods.

Water treatment plants typically use one of two methods for controlling and monitoring chlorine feeds, Online Reagent feed (DPD) and Amperometric instruments. The systems require costly reagent replacement monthly. While Amperometric sensors do not require reagents, frequent calibration is needed. They suffer from flow dependence and small changes result in loss of calibration, pH dependence, and membrane fouling.

“Water utilities now have a better choice for chlorine monitoring that measures four additional water parameters and provides better information for a fraction of the cost. Our NSF 61 certification allows for direct insertion of the sensor into a pipe. The MP-5 can be installed in virtually any location. There is no need for a waste line, lower maintenance results in labor savings, reagent-free operation, and water savings reduce cost. This sensor is a new option for water treatment problems.” – Michael Silveri, Halogen Systems

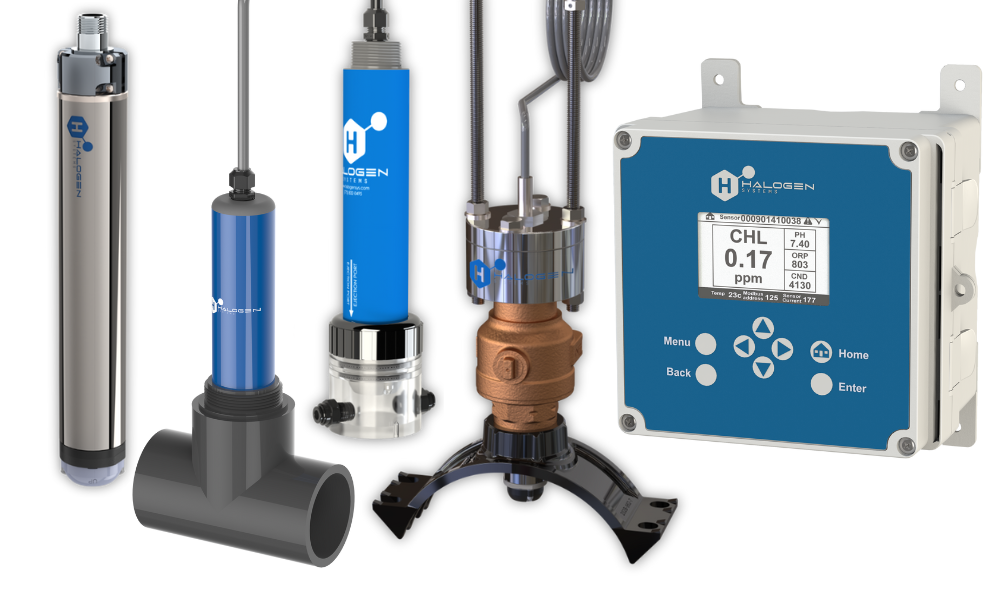

Halogen Systems has created a sensor that cures all the struggles with catering accurate readings with consistency and minimal maintenance. Our flow-independent sensor technology overcomes many limitations of the existing old amperometric systems with far less maintenance. Besides amperometric chlorine measurement, this sensor measures pH, conductivity, temperature, and ORP (oxidation reduction potential).

Existing Amperometric Sensors

All “existing” Amperometric sensors need constant flow, usually by using a waste stream, to maintain their accuracy and calibration. Any pressure spikes or flow changes cause a complete loss of calibration. These sensors produce a waste stream of as much as 65,000 gallons per year, per instrument. The effects of temperature fluctuation cause non-linear signal changes due to membrane characteristics and result in a loss of calibration. A treatment plant in the City of Lakewood, CA, relayed that frequent (weekly or semiweekly) calibration is necessary for the Amperometric Chlorine sensors they have used in the past. Additionally, when the electrolyte becomes diluted, the sensor must be recalibrated, the electrolyte replenished, and the membrane replaced. Most available amperometric chlorine sensor designs limit operation above pH 7.5. pH and values higher than 7.5 are often seen in drinking water systems. Changes in conductivity also influence these sensors. (Australia, 2010)

Limitations of "Old Tech" Amperometric Sensors

- Highly Flow Dependent – this means that they cannot be installed directly in a pipe. They require elaborate flow columns that use a waste stream

- Membrane and electrolyte replacement required

- Frequent calibration

- pH-dependent

- Temperature-dependent

Colorimetric Technology

In the colorimetric method, chemicals added to the sample react with chlorine to produce a color. The darkness of the color is proportional to the amount of chlorine. These instruments are known as Online DPD Instruments (DPD). The color is measured and the result is converted into a ppm chlorine reading. This is the most widely used chlorine instrument by water authorities, however, they have drawbacks. One is reagent cost. Reagents typically last for 30 days. According to one website, reagents for a single system can cost between $750 and $1000 per year, including shipping. Since most water authorities have many of these systems, the annual reagent costs can be significant. These systems are complex and require monthly maintenance by service people.

"Old" Amperometric Chlorine Sensor Technology

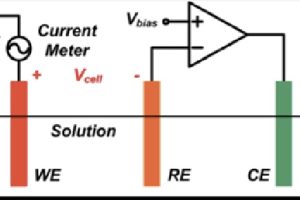

All Amperometric chlorine sensors are electrochemical devices that rely of this reaction to measure chlorine: Electrons flow from the reduction of Hypochlorous acid to chloride at the cathode. This electron flow is measured by the sensor. There are two basic designs: Bare and Membrane. In a Bare Electrode system, the three-electrode Amperometric Measurement Method (See below) is used. Voltage is applied between two electrodes using a potentiostat that compensates for solution resistance. The measured current is proportional to the chlorine level.

WE = Working Electrode

RE = Reference Electrode

CE = Counter Electrode

In a Membrane Style system, the two-electrode method is used. It is essentially the same as the three-electrode method, however, the Counter Electrodes and the Reference Electrode are combined and separated from the solution by a membrane. Electrolyte slowly diffuses into the solution and must be replenished periodically. Amperometric sensors are free from many interferences like manganese, iron, and nitrate; substances that interfere with colorimetric methods.

Unique Features Include:

- Flow Independent Chlorine Measurement – this sensor is unaffected by flow velocity changes from 0 to 12 m/s.(HSI 06, 2020). Our chlorine sensor style has an integrated pump, which uses a long-life brushless motor to deliver a fixed velocity across the electrodes, creating a measure of flow independence—the high-velocity flow across the electrodes sensitivity and signal to Noise Ratio.

- Connects Directly to a SCADA System– the sensor can be connected directly to a Supervisory Control and Data Acquisition system (SCADA) or a Programmable Logic Controller via Modbus, allowing us to cut out the cost of a separate and optional Display Module.

- Self-Cleaning– An electrochemical cleaning method resists polarization and adsorption of organics. The integrated cleaning beads continuously clean the sensor, keeping the electrode surfaces, including the pH sensor, free from the buildup of hardness and biofouling. The solid metal electrodes last the life of the system.

- Long Interval Between Calibrations– These features combine to enable long intervals between calibrations. In our freshwater tests, calibrations were stable for more than three months.

Halogen Systems Inc. - MP5™

Since this sensor is installed in water mains where NSF 61 certification is required. The sensor uses common wet installation methods and componants. This sensor is also compliant as are other amperometric DPD instruments. The side stream version of the sensor can be installed for either temporary or permanent monitoring of water treatment branches. The sensor requires only a small flow of 0 to 0.5 GPH for operation. 12 or 24VDC power can be used. The sensor can also be connected to a SCADA system for real-time monitoring. A ¼” ID tube is used for water sampling. Since the sensor does not require any flow, it can be installed in a tank.

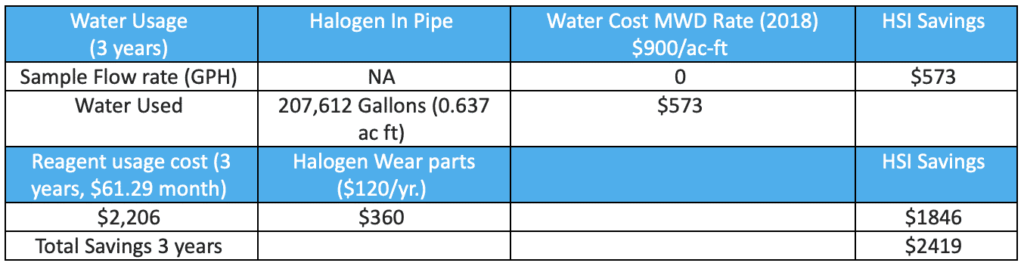

Reducing Total Cost Of Ownership

Online DPD instruments that measure chlorine need chemical reagents with monthly replenishment. Both methods need flow regulation and produce a waste stream with a flow rate of about 500 mL per minute that totals up to 69,204 gallons per year per instrument. (Emerson, 2018) Depending on the water source, this costs $191 per year (at MWD Rates) per instrument. These systems also need the infrastructure to drain this waste stream. In many locations, this is not practical. Our flow-independent chlorine analyzer provides the ability to install a chlorine analyzer at each location without all the infrastructures, resulting in far greater reliability and protection of the public they serve. Below is a summary of the relative costs of both the colorimetric and the flow-independent sensor.

Ease Of Service

Our NSF-61 certified chlorine sensor is able to be installed in a wet tap installation method. This enabels a utility to directly insert our chlorine analyzer into a distribution pipe with no supportive infrastructure. The highly integrated design reduces cost and size while increasing reliability.

Better Information With Additional Parameters

Our multiparameter chlorine analyzer measures four additional parameters within a single compact package. A total of five measurements provide the utility with information far beyond the free chlorine level. There is no need for recalibration under changing water conditions.

Traditional discrete sensorsystems with a similar number of parameters often cost five or six times as much as Halogen Systems Inc. MP5™.

Parameters Measured

- Amperometric Free Chlorine – Our patented sensor measures free chlorine every 55 seconds. The readings are pH, temperature and conductivity compensated.

- Integrated pH sensor: The MP-5 has a two-year life expectancy versus the industry average of six months. Our sensor cartridge is an integral part of the sensor. Because of this, we designed our chlorine sensor so that it self-cleans continuously. We use a unique pH sensor that tolerates pressures up to 150 PSI. The pH sensor is shipped dry, wets out within minutes, and does not need frequent calibration.

- Integrated Conductivity Sensor: Changes in water conductivity is an integral way for water utilities to determine water quality. These shifts can indicate contamination, a pollution event, or other problems.

- Oxidation-Reduction Potential (ORP): Measuring ORP in drinking water is another indicator of possible contamination or pipe failure. Our chlorine sensor has a unique method of measuring ORP and keeps the electrodes clean.

References:

Australia, W. Q. (2010). Development of Tools for Improved Disinfection Control within Distribution Systems. WQRA.

DoD. (2020, July 07). SBIR-STTR-Sucess: Halogen Systems, Inc. Retrieved from sbir.gov: https://www.sbir.gov/node/1704083

Emerson. (2018). https://www.emerson.com/documents/automation/white-paper-effective-chlorine-analysis-for-disinfection-en-5463798.pdf. Retrieved from Emerson.com: https://www.emerson.com/documents/automation/white-paper-effective-chlorine-analysis-for-disinfection-en-5463798.pdf

HSI 04. (2020). Halogen ISO 15839 Field Test. White Paper 04

HSI 06. (2020). Amperometric Flow Sensor Test Report. White Paper 06