Sensor is ideally suited for New Jersey Legionella Compliance

- Home

- Sensor is ideally suited for New Jersey Legionella Compliance

- 10 December 2024

New Sensor Ideally Suited for Remote Water Quality Monitoring

Introduction

In the landscape of water treatment, compliance with stringent regulations like New Jersey’s SB2188 is crucial for ensuring public health, particularly in the prevention of Legionella. This law mandates a minimum concentration of 0.3 mg/L of free chlorine or 1.0 mg/L of monochloramine in public water systems. To achieve this, operators need effective, reliable monitoring tools that do not compromise the system’s integrity or efficiency.

The Challenge: Traditional Sensor Limitations

Traditional chlorine sensors pose significant challenges, including the requirement for a substantial waste stream — around 70,000 gallons per year per sensor. This not only increases operational costs but also impacts water conservation efforts. Moreover, these sensors are often not suited for direct integration into existing distribution networks without significant adaptation.

Introducing Halogen Systems' MP5 Sensor

NSF61 Certification

Ensures that the sensor meets public health and safety standards for materials used in drinking water systems.

Flow and Pressure Independence

The sensor's design allows for accurate readings regardless of flow or pressure, making it ideal for diverse installation scenarios, from high-pressure pipelines to static tanks.

Installation Flexibility

With the capability for "wet tapping," the sensor can be installed into active pipelines using standard corp stop valves, reducing downtime and complexity. It's also suitable for immersion in tanks, where traditional sensors might fail due to zero flow conditions.

No Waste Stream

This sensor eliminates the need for a waste stream, saving approximately 70,000 gallons of water per year, per sensor, enhancing sustainability.

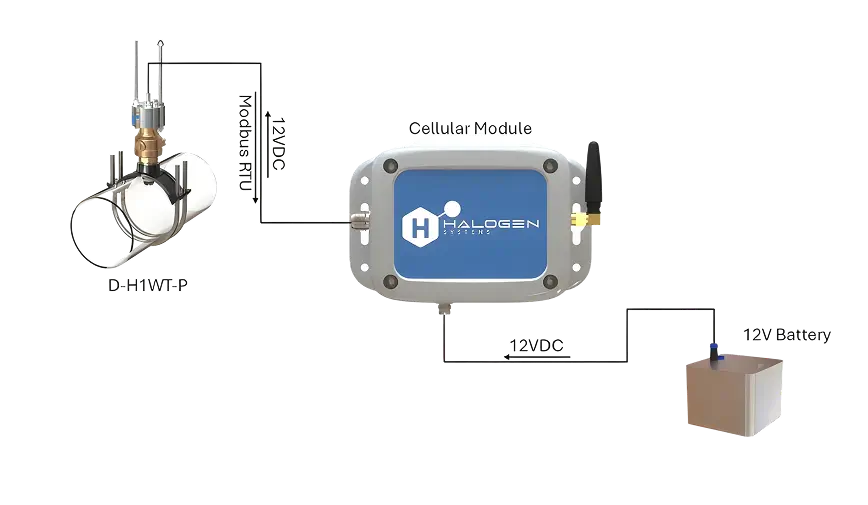

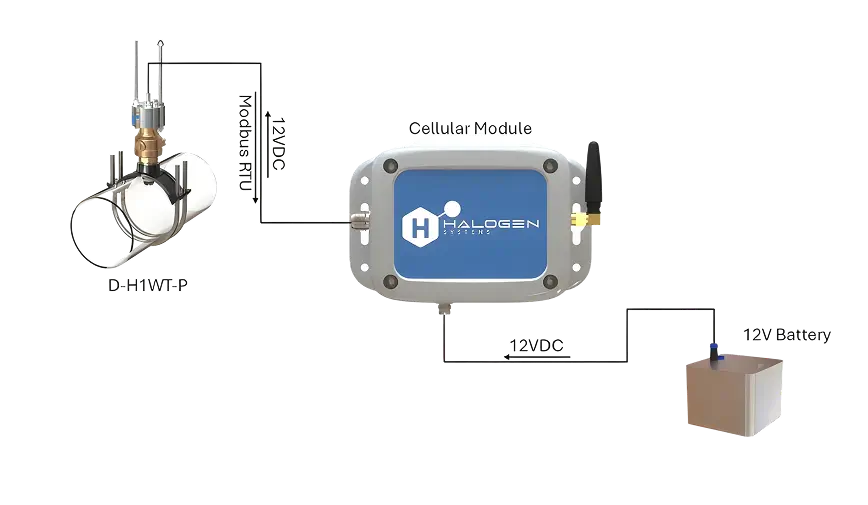

Battery Operation

Recent innovations mean the sensor can operate for six months on battery power, facilitating remote installations where power supply might be an issue.

Maintenance-Free Operation

The sensor requires no maintenance for six months, allowing for unattended operation, which is particularly beneficial for remote or hard-to-reach installations.

Data Management

Equipped with a cellular IoT modem, the sensor supports cloud monitoring. Data can be integrated into existing SCADA systems or through platforms like the SENSUS AMI Network, as demonstrated in a recent trial in Gainesville, GA. This trial, detailed in a webinar at Water Online, showcased how the sensor could provide 24/7 monitoring capabilities.

Measurement Capabilities

The Halogen Interface Module can measure and report on Free Chlorine, pH, Conductivity, and Temperature, with a specific version available for municipalities using Monochloramine.

Compliance and Efficiency

The Halogen Systems’ MP5 Sensor is not just about meeting regulatory requirements; it’s about enhancing operational efficiency, reducing costs, and minimizing environmental impact. The sensor’s design directly addresses the challenges posed by traditional monitoring methods, offering a scalable, reliable solution for water quality management across various municipal systems.

Conclusion

For drinking water treatment operators, especially those in regions like New Jersey facing strict water quality laws, Halogen Systems’ MP5 Sensor is a game-changer. It provides a versatile, efficient, and sustainable approach to monitoring, ensuring compliance, protecting public health, and managing water resources more effectively. This technology not only simplifies the monitoring process but also proves to be a step forward in proactive water management and conservation.

Legionella prevention strategies

Water conservation technologies

more technical details

- 10 December 2024

New Sensor Ideally Suited for Remote Water Quality Monitoring

Introduction

In the landscape of water treatment, compliance with stringent regulations like New Jersey’s SB2188 is crucial for ensuring public health, particularly in the prevention of Legionella. This law mandates a minimum concentration of 0.3 mg/L of free chlorine or 1.0 mg/L of monochloramine in public water systems. To achieve this, operators need effective, reliable monitoring tools that do not compromise the system’s integrity or efficiency.

The Challenge: Traditional Sensor Limitations

Traditional chlorine sensors pose significant challenges, including the requirement for a substantial waste stream — around 70,000 gallons per year per sensor. This not only increases operational costs but also impacts water conservation efforts. Moreover, these sensors are often not suited for direct integration into existing distribution networks without significant adaptation.

Introducing Halogen Systems' MP5 Sensor

NSF61 Certification

Ensures that the sensor meets public health and safety standards for materials used in drinking water systems.

Flow and Pressure Independence

The sensor's design allows for accurate readings regardless of flow or pressure, making it ideal for diverse installation scenarios, from high-pressure pipelines to static tanks.

Installation Flexibility

With the capability for "wet tapping," the sensor can be installed into active pipelines using standard corp stop valves, reducing downtime and complexity. It's also suitable for immersion in tanks, where traditional sensors might fail due to zero flow conditions.

No Waste Stream

This sensor eliminates the need for a waste stream, saving approximately 70,000 gallons of water per year, per sensor, enhancing sustainability.

Battery Operation

Recent innovations mean the sensor can operate for six months on battery power, facilitating remote installations where power supply might be an issue.

Maintenance-Free Operation

The sensor requires no maintenance for six months, allowing for unattended operation, which is particularly beneficial for remote or hard-to-reach installations.

Data Management

Equipped with a cellular IoT modem, the sensor supports cloud monitoring. Data can be integrated into existing SCADA systems or through platforms like the SENSUS AMI Network, as demonstrated in a recent trial in Gainesville, GA. This trial, detailed in a webinar at Water Online, showcased how the sensor could provide 24/7 monitoring capabilities.

Measurement Capabilities

The Halogen Interface Module can measure and report on Free Chlorine, pH, Conductivity, and Temperature, with a specific version available for municipalities using Monochloramine.

Compliance and Efficiency

The Halogen Systems’ MP5 Sensor is not just about meeting regulatory requirements; it’s about enhancing operational efficiency, reducing costs, and minimizing environmental impact. The sensor’s design directly addresses the challenges posed by traditional monitoring methods, offering a scalable, reliable solution for water quality management across various municipal systems.

Conclusion

For drinking water treatment operators, especially those in regions like New Jersey facing strict water quality laws, Halogen Systems’ MP5 Sensor is a game-changer. It provides a versatile, efficient, and sustainable approach to monitoring, ensuring compliance, protecting public health, and managing water resources more effectively. This technology not only simplifies the monitoring process but also proves to be a step forward in proactive water management and conservation.

Legionella prevention strategies

Water conservation technologies

more technical details