Water Quality Monitoring for Legionella Control

- Home

- Water Quality Monitoring for Legionella Control

- 10 December 2024

Sensors are the Missing Link for Legionella Control in Buildings and Hospitals

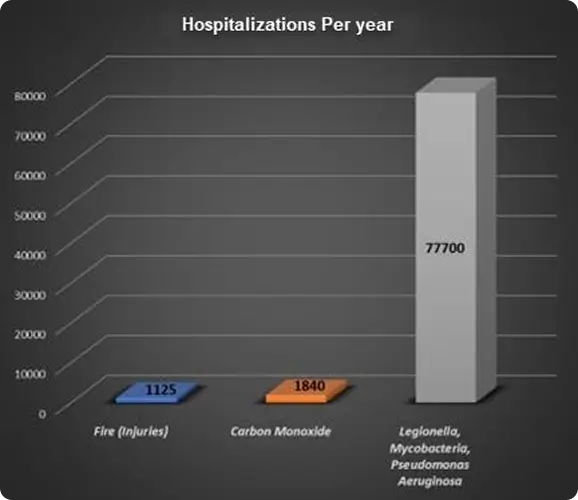

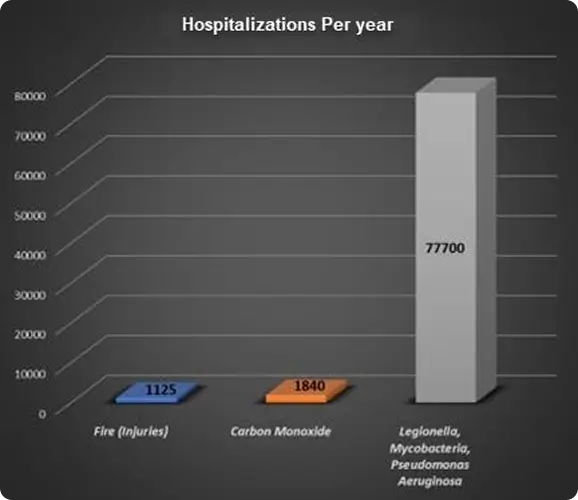

While hazards like carbon monoxide are routinely monitored with sensors, CO results in far fewer hospitalizations than Legionella Figure 1. Water quality monitoring can prevent or rapidly identify conditions that lead to its growth. The answer is that existing water quality sensors are very difficult to add to a building’s hot water loop.

Most building professionals know Legionella is a high risk even to healthy people and that:

Water Quality is a good indicator of Legionella.

There are guidelines for monitoring water quality parameters, chlorine, pH, temperature from CDC and FEMA, ASHRAE, VHA, ASDWA and others. The cost of making manual measurements is expensive, labor intensive ($26,000 per year*) and require training. There is new sensor technology that makes it practical to monitor water quality throughout a building’s hot water system. It is the only sensor with NSF61 Certification for potable water. It is installed directly in hot water loop piping. Legionella management software to minimize the risk of Legionnaires Disease, like LAMPS is a great help but with sensor monitoring technology, it is even more effective. It enables monitoring of more points on a 24/7 basis. Existing sensors are wasteful, expensive and impractical for use in hot water systems They are primarily used in the chemical feed location, not monitoring points, for these reasons:

Sensors require a waste stream of 70,000 gallons per year. A typical wasted water cost is $400** per year per sensor. This waste stream requires energy to be heated. With natural gas this is about $950*** per year.

Chlorine sensors often use reagents that cost over $700 per year.

Installing these sensors requires a sewer connection which can add thousands to the installation cost.

They require high maintenance, frequent calibration and knowledgeable technicians for weekly or monthly maintenance

They typically measure only one parameter, while ASHRAE and CDC recommend three or four.

New Sensors make monitoring practical

The MP-HOT Sensor from Halogen Systems, Inc. can be installed almost anywhere. This sensor is based on a new technology originally funded by the Office of Naval Research for the US Navy. Benefits include:

No waste stream

Install anywhere with direct pipe insertion

NSF61 Certified for drinking water contact in Commercial Hot Water

Flow and pressure independent

No maintenance for 6 to 12 months

Measures all the ASHRAE 541 recommended parameters

chlorine, pH, conductivity and temperature

A new sensor measures monochloramine

Integrates with LAMPS water management software

These new sensors can be located throughout the hot water loops to identify problems or confirm safety. Some projects are planning on 60 to 90 of these sensors to control Legionella in hospitals.

Remote monitoring via cellular or Wi-Fi is an option for building operators and managers and makes possible 24/7 monitoring. Water quality impacts heating, cooling efficiencies, and energy bills. Biofilm increases pumping and electricity costs. Just 2 millimeters of calcium carbonate scale and biofilm can boost energy costs by 50%, according to Montana State University. Water quality can deteriorate over time, leading to pathogen growth, bad taste and odor, metal extraction, and infrastructure damage through microbial induced corrosion (MIC). Data from Microbial Biotechnology in 2021 show that at least 20% of corrosion is due to MIC.

MP-HOT is a new tool to ensure building operators are proactively maintaining building resilience. There are increasing regulatory requirements for monitoring water quality. Many are in effect and others are coming. See New Jersey SB2188 as an example. MP-HOT is a very low maintenance sensor that is not only effective but cost effective.

Authors: David J. Swiderski, Senior Technical Strategist of HC Info (www.hcinfo.com and Michael Silveri, President of Halogen Systems inc. (www,halogensys.com).

- CDC. Carbon Monoxide Poisoning. https://www.cdc.gov/co/faqs.htm

- Collier S, Deng L, Adam E, et al. 2021. Estimate of Burden and Direct Healthcare Cost of Infectious Waterborne Disease in the

United States. Emerging Infectious Diseases. https://stacks.cdc.gov/view/cdc/99960/cdc_99960_DS1.pdf

- Sircar K, Clower, J, Shin M, et al. 2015. Carbon monoxide poisoning deaths in the United States, 1999 to 2012. The American

Journal of Emergency Medicine 33, 9. https://www.sciencedirect.com/science/article/abs/pii/S0735675715003800

- Nonresidential Building Fire Trends (2010-2019). National Fire Data Center (FEMA).

https://www.usfa.fema.gov/downloads/pdf/statistics/fire-estimate-summary-series.pdf

- Manual Measurements $50 hourly rate (including labor burden) x 1.25 hours (including transit time) = $62.50 per site X 8 sites

X 52 weeks =$26,000

- Cost of Water: Total gallons per year: 70,000 @ a cost of $0.007 = $490

- Cost of Energy: The cost of heating 70,000 gallons of water from 60°F to 140°F would be 791 Therms. At $1.20 per Therm,

annual cost is $949.63.

- 10 December 2024

Sensors are the Missing Link for Legionella Control in Buildings and Hospitals

While hazards like carbon monoxide are routinely monitored with sensors, CO results in far fewer hospitalizations than Legionella Figure 1. Water quality monitoring can prevent or rapidly identify conditions that lead to its growth. The answer is that existing water quality sensors are very difficult to add to a building’s hot water loop.

Most building professionals know Legionella is a high risk even to healthy people and that:

Water Quality is a good indicator of Legionella.

There are guidelines for monitoring water quality parameters, chlorine, pH, temperature from CDC and FEMA, ASHRAE, VHA, ASDWA and others. The cost of making manual measurements is expensive, labor intensive ($26,000 per year*) and require training. There is new sensor technology that makes it practical to monitor water quality throughout a building’s hot water system. It is the only sensor with NSF61 Certification for potable water. It is installed directly in hot water loop piping. Legionella management software to minimize the risk of Legionnaires Disease, like LAMPS is a great help but with sensor monitoring technology, it is even more effective. It enables monitoring of more points on a 24/7 basis. Existing sensors are wasteful, expensive and impractical for use in hot water systems They are primarily used in the chemical feed location, not monitoring points, for these reasons:

Sensors require a waste stream of 70,000 gallons per year. A typical wasted water cost is $400** per year per sensor. This waste stream requires energy to be heated. With natural gas this is about $950*** per year.

Chlorine sensors often use reagents that cost over $700 per year.

Installing these sensors requires a sewer connection which can add thousands to the installation cost.

They require high maintenance, frequent calibration and knowledgeable technicians for weekly or monthly maintenance

They typically measure only one parameter, while ASHRAE and CDC recommend three or four.

New Sensors make monitoring practical

The MP-HOT Sensor from Halogen Systems, Inc. can be installed almost anywhere. This sensor is based on a new technology originally funded by the Office of Naval Research for the US Navy. Benefits include:

No waste stream

Install anywhere with direct pipe insertion

NSF61 Certified for drinking water contact in Commercial Hot Water

Flow and pressure independent

No maintenance for 6 to 12 months

Measures all the ASHRAE 541 recommended parameters

chlorine, pH, conductivity and temperature

A new sensor measures monochloramine

Integrates with LAMPS water management software

These new sensors can be located throughout the hot water loops to identify problems or confirm safety. Some projects are planning on 60 to 90 of these sensors to control Legionella in hospitals.

Remote monitoring via cellular or Wi-Fi is an option for building operators and managers and makes possible 24/7 monitoring. Water quality impacts heating, cooling efficiencies, and energy bills. Biofilm increases pumping and electricity costs. Just 2 millimeters of calcium carbonate scale and biofilm can boost energy costs by 50%, according to Montana State University. Water quality can deteriorate over time, leading to pathogen growth, bad taste and odor, metal extraction, and infrastructure damage through microbial induced corrosion (MIC). Data from Microbial Biotechnology in 2021 show that at least 20% of corrosion is due to MIC.

MP-HOT is a new tool to ensure building operators are proactively maintaining building resilience. There are increasing regulatory requirements for monitoring water quality. Many are in effect and others are coming. See New Jersey SB2188 as an example. MP-HOT is a very low maintenance sensor that is not only effective but cost effective.

Authors: David J. Swiderski, Senior Technical Strategist of HC Info (www.hcinfo.com and Michael Silveri, President of Halogen Systems inc. (www,halogensys.com).

- CDC. Carbon Monoxide Poisoning. https://www.cdc.gov/co/faqs.htm

- Collier S, Deng L, Adam E, et al. 2021. Estimate of Burden and Direct Healthcare Cost of Infectious Waterborne Disease in the

United States. Emerging Infectious Diseases.

- Sircar K, Clower, J, Shin M, et al. 2015. Carbon monoxide poisoning deaths in the United States, 1999 to 2012. The American

Journal of Emergency Medicine 33, 9.

- Nonresidential Building Fire Trends (2010-2019). National Fire Data Center (FEMA).

- Manual Measurements $50 hourly rate (including labor burden) x 1.25 hours (including transit time) = $62.50 per site X 8 sites

X 52 weeks =$26,000

- Cost of Water: Total gallons per year: 70,000 @ a cost of $0.007 = $490

- Cost of Energy: The cost of heating 70,000 gallons of water from 60°F to 140°F would be 791 Therms. At $1.20 per Therm,

annual cost is $949.63.