About Us

- Home

- About Us

Who is HSI?

Started in a garage in a small town in Nevada, Halogen Systems, Inc. qualified for a Small Business Innovative Research Contract (SBIR) from the Office of Naval Research (ONR) via a program for the US Navy. Halogen developed a residual chlorine analyzer that met parameters most industry insiders felt were impossible. In 2021, Halogen began extending this proven technology into additional industries, starting with Drinking Water systems, both large and small. Halogen has been deployed in additional sectors such as offshore wind farms, environmental water recovery (EWR) systems such as rainwater collection, cooling towers, greywater systems, and industrial hot-water systems.

Nobody thought that an amperometric sensor would be durable enough to handle in-pipe pressures, much less going from 0 to 140 psi in under 4 minutes, in saltwater, in silty harbors without any drift for months, but they did it, and it’s amazing.

BWMS Engineer

In 40 years of Drinking Water plant experience, I have never seen anything as impressive as the MP5™. The flexibility, functionality, and stability are unmatched. Period.

DW Systems Engineer

Halogen Systems, Inc is focused on solving difficult water-monitoring issues with innovative technology

Monitoring residual chlorine in drinking water technology for decades required complicated flow-control piping, membranes, and reagents. That complexity created a standardized culture of constant maintenance because the residual chlorine analyzers were isolated from the main flow (sometimes hundreds of feet away), which may have caused measurements to be delayed by five minutes or more.

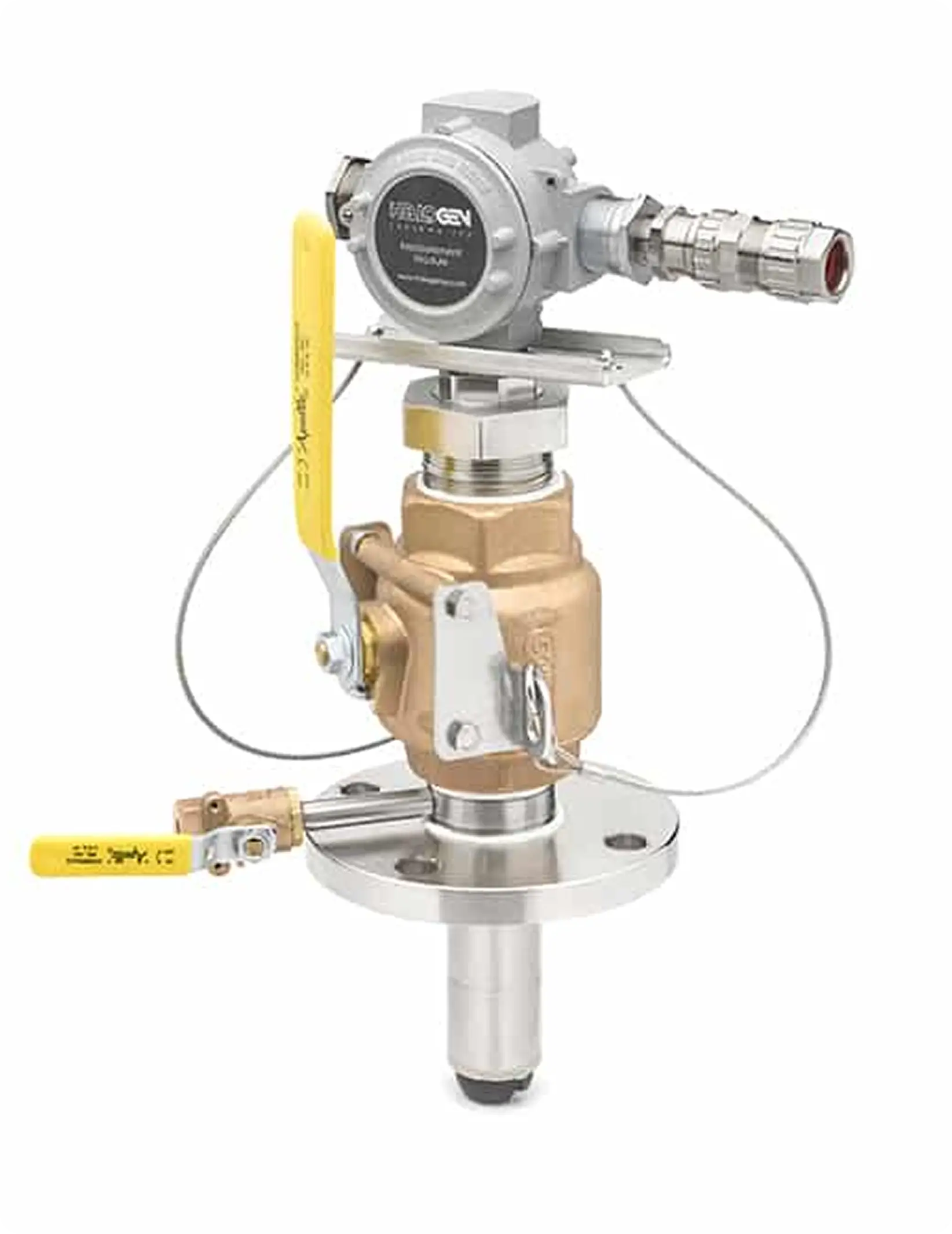

Halogen’s amperometric chlorine analyzer technology allows a sensor to be inserted directly into a pipe. Durable and non-reactive, no flow control or waste drain is needed, and the sensor’s calibration remains constant under virtually any pressure or flow. Even a dry pipe won’t shake the calibration.

With Halogen’s technology, the days of constant maintenance for chlorine sensors are over. The absence of membranes or reagents means that maintenance requirements have been significantly reduced, leading to substantial cost and time savings. This shift has been particularly beneficial for Ballast Water Management Systems (BWMS) manufacturers, and the Drinking Water industry is also enjoying the advantages of this residual chlorine analyzer, with NSF-61 Certification and approval for the EPA EPA Method 334.0 compliance reporting.

Halogen’s technology has not only revolutionized ballast water monitoring but also demonstrated its adaptability to different industries. It has successfully addressed long-standing challenges in the Marine Ballast Water Management industry, and now, Halogen is leveraging this experience to solve mission-critical problems in industries like Drinking Water, Commercial Hot Water Systems, and Environmental Water Reclamation. Its simplicity, accuracy, and stability make it a versatile solution for a wide range of applications.

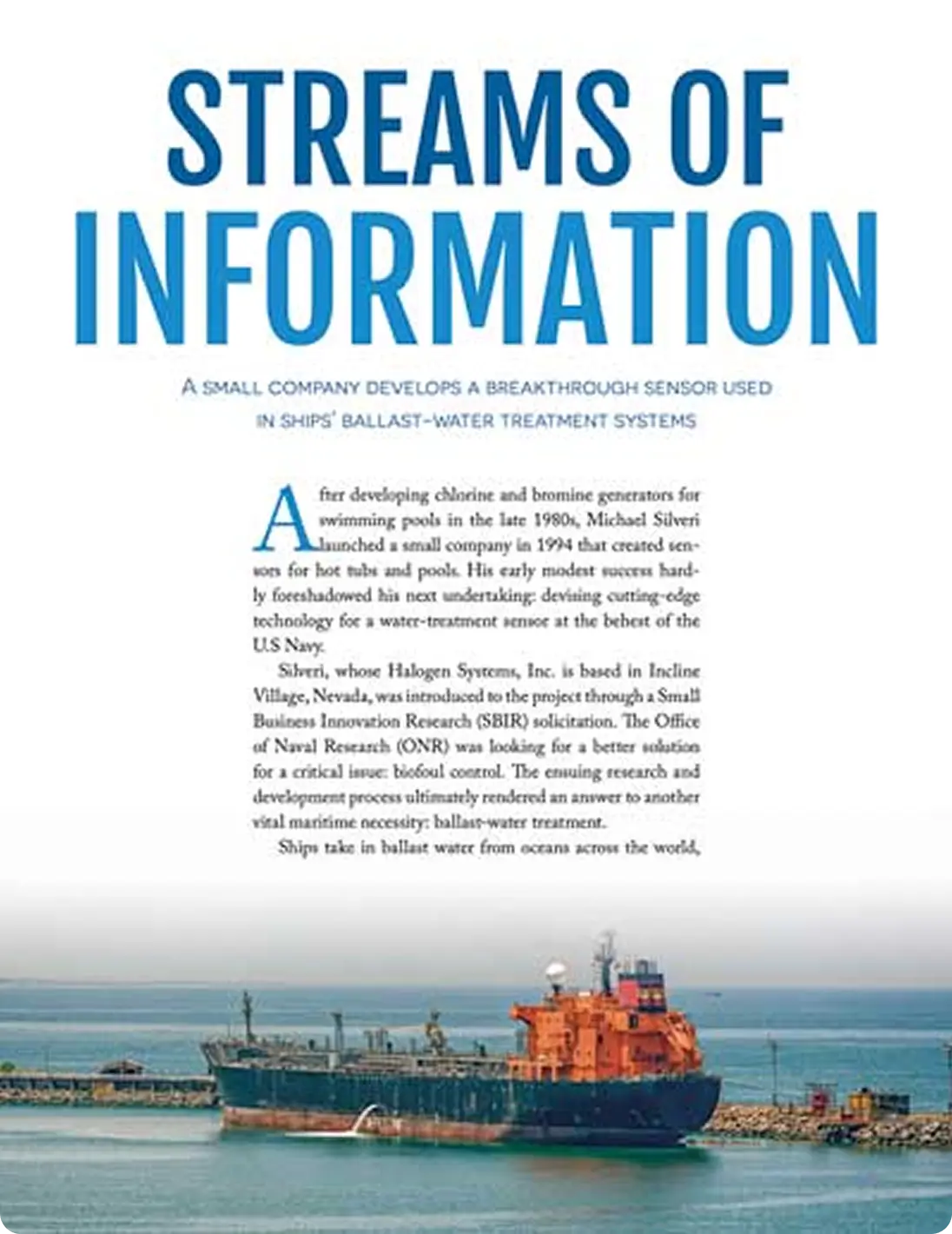

Ballast Water Treatment For Invasive Species

Invasive species (like zebra mussels) create environmental havoc on ecosystems. Many of these organisms are brought in by ballast water from cargo ships crossing oceans or different harbors. These ships discharge, at times, millions of gallons of water during operation. Untreated water can result in overwhelming local ecosystems. Fortunately, vessels are now required to sterilize their ballast water and kill invasive species before discharging it using a treatment system (BWTS). Many BWTS use the Halogen Systems Inc. Ballast Water TRO Sensor to measure the oxidant level for controlling the treatment process. Halogen’s TRO sensor also ensures that the discharged water’s oxidant level is safe to be released. Ballast water chlorine measurement is the most difficult of all applications due to biofouling, high water hardness, high salt levels, and temperature extremes.

Halogen’s technology allows a sensor to be inserted directly into a ballast water pipe, or a drinking water flow. Durable and non-reactive, no flow-control or waste drain is needed and the sensor’s calibration remains constant in any pressure or flow. Even a dry pipe won’t shake the calibration.

Halogen’s innovative technology has effectively addressed persistent challenges in ballast water monitoring, even under challenging operational circumstances, by offering a combination of simplicity, precision, and reliability. Today, Halogen is leveraging the valuable insights gained from the demanding Marine Ballast Water Management sector to tackle crucial issues in various industries such as Drinking Water, Wastewater, Commercial Hot Water Systems, and Environmental Water Reclamation.

Municipal Drinking Water Online Chlorine Analyzer

It took us several years to generate a reliable sensor for such a harsh environment as seawater. Since we have successfully provided a sensor for the most strenuous application, developing similar sensor technology for drinking water treatment plants is comparatively easy.

Since this technology does not use membranes or reagents, maintenance requirements for residual chlorine analyzers can go from constant to minimal. Manufacturers of Ballast Water Management Systems (BWMS) and Marine regulators saw immediate benefits. Now, the Drinking Water industry is taking note, with both NSF-61 Certification and approval for EPA EPA Method 334.0 compliance reporting.

The Halogen Sensor has been granted 11 patents worldwide and is the only online chlorine sensor with NSF61 certification. This allows it to be inserted directly into a drinking water pipe without a required waste stream. It can do this because it is the only sensor unaffected by fluctuating flow speed or pressure. The flow-generating technology also means that Halogen’s sensors work just as effectively when suspended or placed in a water tank.

Standard Membrane and reagent residual chlorine sensors (such as the Hach CL17) require a waste stream of roughly 70,000 gallons of water per year to obtain their readings. Besides excessive water consumption, the cost of the treated water simply going to waste is, on average, $150 per year per sensor. Some utilities have over 100 analyzers operating with waste streams, resulting in a significant wasteful expense. The waste stream from such old-technology sensors cannot simply be discharged into the environment and requires additional chemical reagents, typically adding an average of $700 per year per analyzer plus labor. With NSF-61 Certification and no need for waste streams or reagents, Municipal drinking water utilities worldwide are already benefiting from using the residual chlorine analyzer.

Online Chlorine Analyzer Designed for Simplicity and Flexibility

Whether designing a complete Ballast Water Management System (BWMS) or Municipal Drinking Water facility, architects, engineers, and operators appreciate the confidence they gain from Halogen’s remarkable calibration stability as much as they enjoy the flexible installation types and near-zero maintenance. Contact Halogen today to learn more about designing your system for flexibility and simplicity.