Lakewood CA

- Home

- Lakewood CA

Lakewood CA

- Home

- Lakewood CA

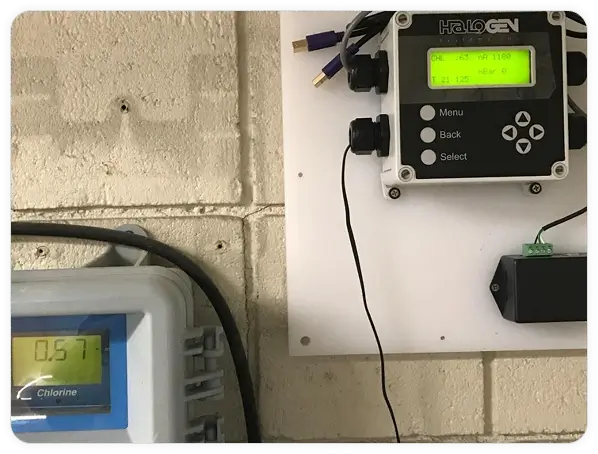

Initial Flow Cell Installation

Operating since April 2021

Started up with no calibration or flow adjustment

0.05 ppm difference from DPD with no drift

Wet Tap In-Pipe Version

The success with the flow cell prompted interest in Halogen’s wet tap version, which was trialed once it received NSF61 and NSF372 certifications. Initial challenges with the wet tap version related to water pressure were resolved through design modifications by Michael Santillan, the City’s Water Field Operations Manager. After these adjustments, the sensor was installed at a well site without existing monitoring, Soon after installation, the sensor quickly alerted operators to a drop in chlorine residual, allowing swift action to maintain water quality.

Without Halogen’s wet tap sensor, the well may have continued to deliver water with very little chlorine residual. The City realized the importance of continuous monitoring at each well location.

Following this success, Lakewood plans to expand the use of Halogen’s wet tap sensors across other well locations for continuous chlorine residual monitoring in the distribution system. Over two years of operation, these sensors have not required calibration or service.

Authors

Derek Nguyen, Ph.D., P.E. and Michael Santillan – City of Lakewood, Derwin Dy, P.E., and Michael Silveri – Halogen Systems, Inc.

Flow Independent

Operates effectively regardless of flow rate changes.

Self-Cleaning

Minimizes maintenance by automatically cleaning itself.

Multi-parameter

Measures up to five parameters, enhancing monitoring capabilities.

Monitoring Chlorine in a Distribution System

The City of Lakewood, which exclusively uses groundwater from the Central Basin Groundwater Basin, operates 11 deep wells, 180 miles of water mains ranging from 4 to 27 inches in diameter, three storage facilities with a capacity of 13 million gallons, and two treatment facilities. This setup allows the city to pump approximately 6,500 acre-feet of water annually.

The city had been seeking a chlorine sensor that does not produce a waste stream, as some wells were not equipped to handle the wastewater from traditional chlorine analyzers. Previously, chlorine residuals were verified through daily grab samples, but this method did not provide real-time alerts if chlorine injection failed due to issues like air locking, pump failure, or leaks in the chlorine feed line.

Traditional amperometric sensors and DPD instruments typically generate a waste stream, using up to 69,000 gallons of water annually, which translates to 0.2 acre-feet or $690 in non-revenue water at the city’s rates. Amid California’s ongoing drought concerns, water conservation has become critical, prompting the search for more efficient technologies.

In 2018, Lakewood’s then Assistant Director of Water Resources, Derwin Dy, began looking for an NSF-61 approved chlorine analyzer that did not generate a waste stream. He discovered Halogen Systems’ chlorine analyzer, which, although not yet NSF approved, showed promise. Through collaboration with Michael Silveri from Halogen Systems and connections made at AWWA conferences, the technology was further developed.

By April 2021, Halogen introduced their prototype, the MP5 sensor, which Lakewood tested at one of its booster stations alongside the existing Hach CL17 analyzer. The Halogen sensor was installed without a flow regulator, had a simple start-up, and its readings were accurate within 0.04 ppm of the Hach CL17. Over six months, it required only minor maintenance for manganese buildup, and no calibration was needed. This experience was completely different than membrane style amperometric sensors that weekly

calibration in addition to other periodic maintenance. After this period, the city decommissioned the Online DPD system, trusting the Halogen sensor’s reliability and accuracy, and continued to verify results with grab samples.

The success with the flow cell prompted interest in Halogen’s wet tap version, which was trialed once it received NSF61 and NSF372 certifications. Initial challenges with the wet tap version related to water pressure were resolved through design modifications by Michael Santillan, the City’s Water Field Operations Manager. After these adjustments, the sensor was installed at a well site without existing monitoring, and its performance was comparable to the flow cell version. The sensor quickly alerted operators to a drop in chlorine residual, allowing swift action to maintain water quality.