Demand Based Flushing

- Home

- Demand Based Flushing

- 2 April 2024

Halogen Sensors are ideal for Remote monitoring of water quality.

Water utilities are charged with managing their systems carefully to ensure high water quality for all their end users. Each day utilities take samples of water quality around the system as required by the EPA Safe Drinking Water Act to ensure a variety of parameters such as chlorine, pH, conductivity, and many more, are within required ranges. Water quality is impacted by a number of factors, including system design, secondary disinfectant/ chlorine dosing, consumption, temperature, and more.

One particular concept of high importance for utilities in water quality management is changes in quality between finished water leaving the plant to when it is consumed at service connections. This time difference is known as water age, and higher water age is typically accompanied by poor water quality as secondary disinfectants degrade over time. Even the best system designs can have water age issues, especially at dead end lines or areas where consumption is just not high enough to maintain proper water age. Water utilities often mitigate water age and water quality issues by discharging water from the system in certain areas. This is known as flushing, and it brings fresh water with higher levels of secondary disinfectant to the area. Many utilities conduct this manually, by rolling trucks and sending field operations personnel to open hydrants or blow off points.

Technological advancements offer new approaches not only in the monitoring of water quality in the system but also in the management of water age and flushing. Online monitoring offers a more real time method for tracking changes in water quality at given points, and can help refine and optimize flushing or chlorine dosing in the distribution system. Up to this point, water quality monitoring devices have offered a single parameter, often require power, are deployed in controlled environments such as treatment plants, and often have reagents requiring regular maintenance. New technologies offer multi-parameters measurement approaches, form factors offering direct insertion into the distribution pipes, and battery powered options which makes installation in the distribution system practical and feasible. Additionally, technologies that tie in with Advanced Metering Infrastructure (AMI) systems stand to offer a more holistic approach to water quality management, consolidating information on water usage in the system, quality measurements, flushing operations, and optimization to one central decision point.

Background

The City of Gainesville, Georgia is well known for Lake Lanier and a robust poultry industry. Behind the flourishing city is a water utility that aims to offer the highest level of service to it’s more than 60,000 end customers. Gainesville has a history of leveraging new technology to advance efficieny and ensure high service levels. They have deployed Advanced Meter Infrastructure (AMI) to remotely monitor and read water usage. Their Sensus FlexNet AMI system also helps them track pressure levels across the city, along with water loss.

Gainesville services rural areas located many miles from its treatment plant. In dead-end sections, water age can be problematic and necessitates periodic flushing to restore chlorine and pH levels to acceptable standards. Water age often results in taste and odor complaints. Without an automated flushing system, crews must be dispatched to manually open valves or hydrants to flush the affected piping sections with newly treated water. Manual flushing involves deploying a truck and often leads to inconsistencies due to workload variations, traffic conditions, weather impacts, and available labor.

Leaning into Remote Management

In order to save staff time and improve water quality, Gainesville looked for ways to remotely manage this flushing. Gainesville established remote flushing sites in problematic areas of the network. They are using the Sensus ally water meter which has an integrated remote shut off valve to operate flushing points. The sites are remotely controlled and operate on a timed schedule. For sites requiring higher flow rates, the City developed a novel automated flushing system that uses a Sensus 2” Omni meter attached to a ClaVal on/off valve. An ally meter controlls the valve. This gives the City a method of remotely controlling flushes as well as a record of flushing volume used, which is of particular importance for tracking water usage and loss. Flushing can now be conducted remotely, at lower rates for longer durations, and during off-peak hours such as evening or night.

Gainesville has an initiative to optimize flushing operations to ensure water quality but avoid over-discharge of water and associated non-revenue water. Optimizing flushing by considering consumption in the system, as well as online water quality information. To achieve this, Gainesville looked to integrate water quality sensors at flushing sites measuring chlorine and pH levels. With this addition, it expects to enable on-demand flushing, with a view to replacing the traditional timed flushes.

In a previous demand-based flushing trial, the City used an online DPD instrument for remote chlorine monitoring but found pH levels rose to unacceptable levels in colder months. It concluded that both pH and chlorine must be monitored. Other issues included maintenance every 45 days and limitations due to freezing temperatures.

The City of Gainesville, GA tested new sensor technology from Halogen Systems, Inc. and identified several advantages compared to the previous equipment

Measures both chlorine and pH

Requires no maintenance or calibration for at least six months.

Installed by wet tapping directly into a main and operates in freezing temperatures without needing service.

Enables battery operation, eliminating utility power needs.

Minimizes Non-Revenue Water (NRW) using no waste stream.

Offers sufficient resolution to trigger flushing when chlorine levels drop to 0.35 ppm or when pH rises to 8.9 or higher

These features are expected to lead to significant NRW savings through fewer flushes and reduced truck rolls, as each flush can require around 140,000 gallons depending on the location and no periodic visits to replace reagents are required.

This new sensor technology incorporates a mechanical and electrochemical self-cleaning system and can be installed directly within a pipe. It is a multiparameter amperometric sensor capable of independently measuring pH, conductivity, ORP, and temperature, regardless of flow and pressure conditions. The self-cleaning feature extends the interval between calibration and maintenance. Installation employs conventional wet tapping equipment in active distribution lines. The service interval is 12 months, with a calibration check required every six months. The sensor operates indefinitely at zero flow and zero chlorine levels without experiencing memory effects common to membrane style sensors.

A new sensor version measures both Free Chlorine and Monochloramine directly in a pipe, without reagents or membranes.

About the Sensor

Sensor Installation

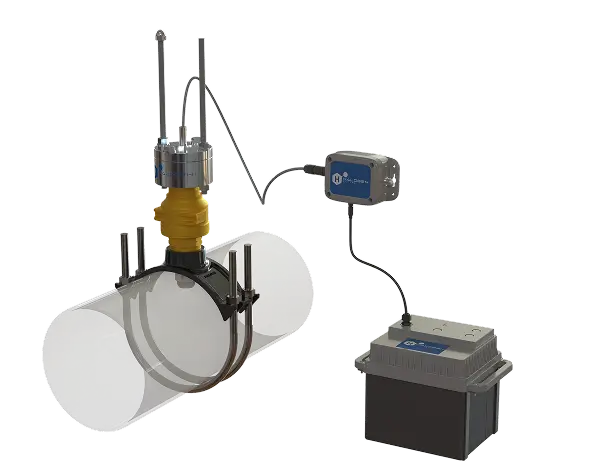

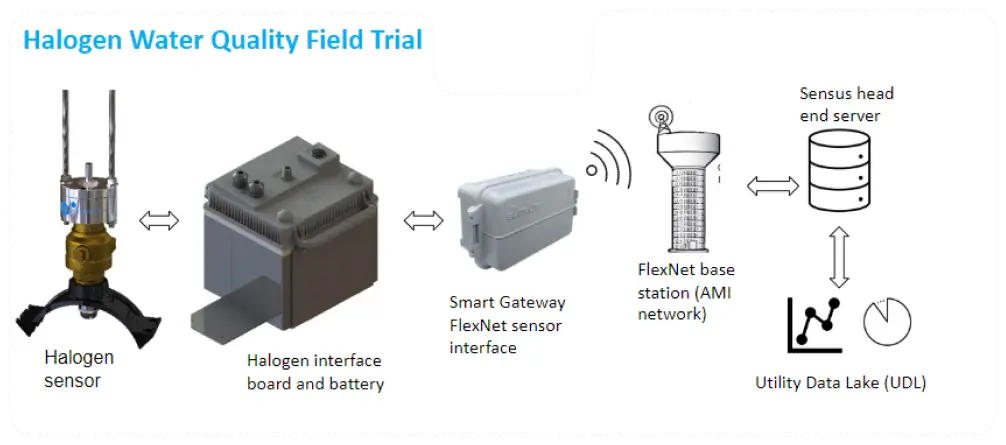

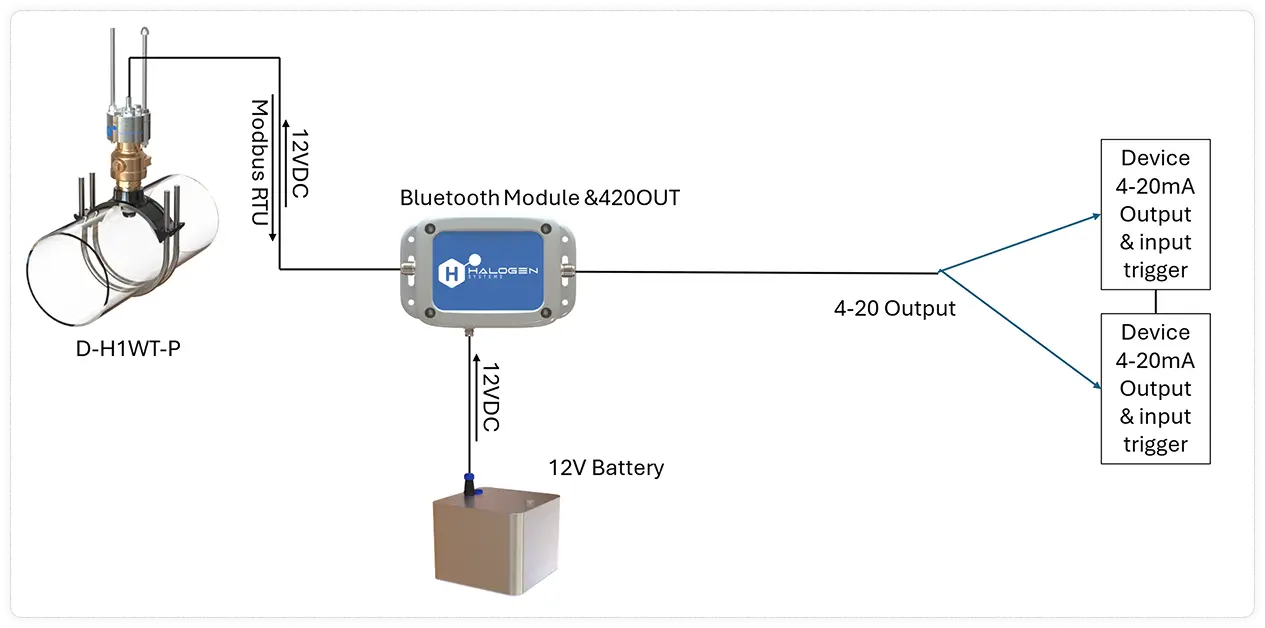

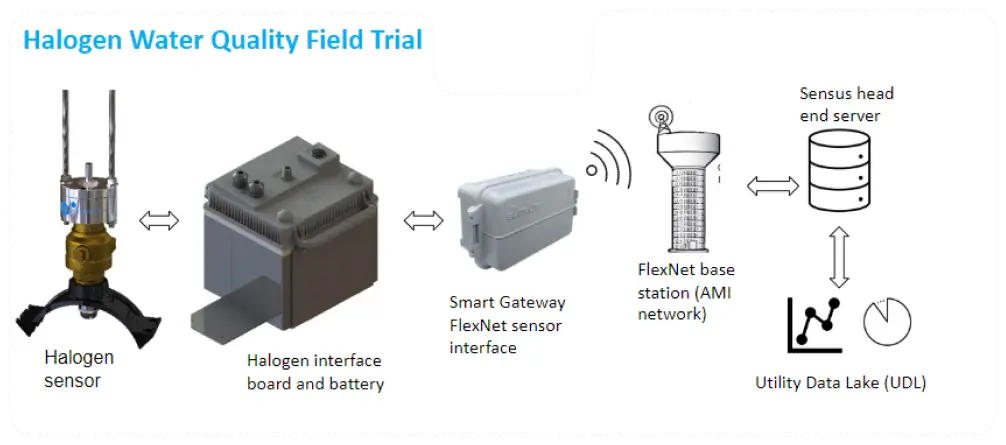

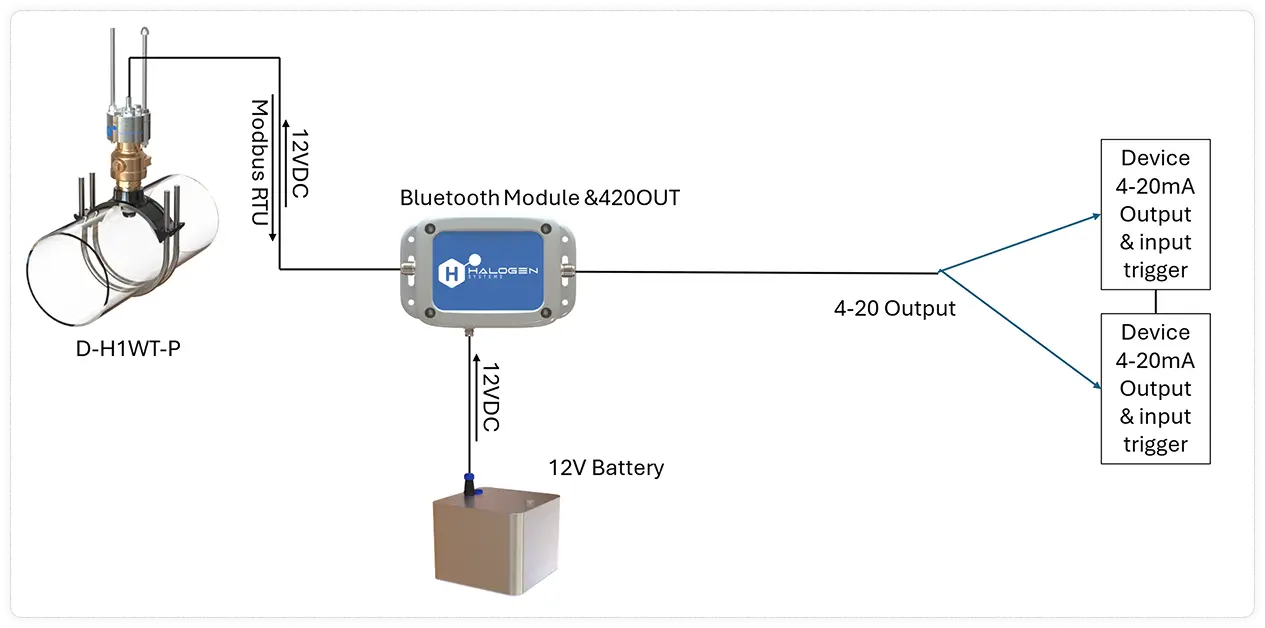

The Halogen MP5-A interface supports low power mode for up to six months of battery operation on a 50AH charge. Four 4-20 mA outputs connect to SENSUS Smart Gateways for data transmission to the Xylem Data Lake Dashboard. Data uploads are triggered by the Smart Gateway every 15 minutes.

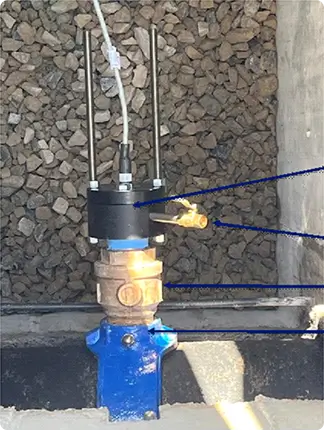

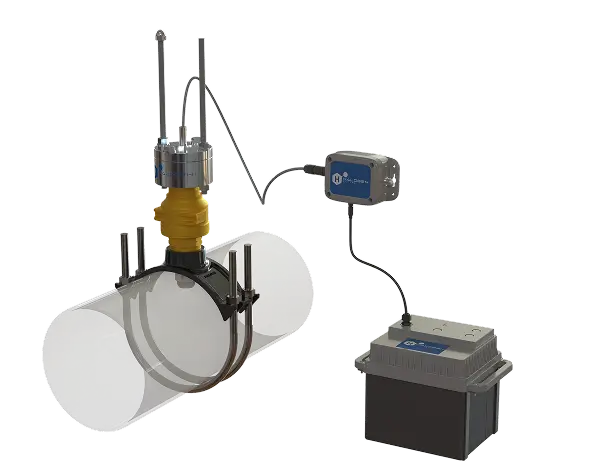

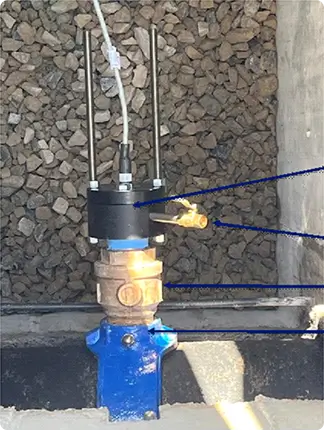

A vault installation was used due to the depth and size of the pipeline. A jumbo meter box or manhole can be used for 7” and smaller diameter pipe. Sensor installation in an active pipeline uses conventional Wet Tapping Equipment. A Corp Stop valve is installed, then the Halogen Sensor with Remover is attached, and the sensor is inserted into the flow. A sample port enables calibration checks using handheld colorimeters.

Figure 3: Wet tap sensor installation into a 16” main using a Corp Stock valve. Integrated remover assembly enables removal of sensor for service and wet tapping of an active pipeline.

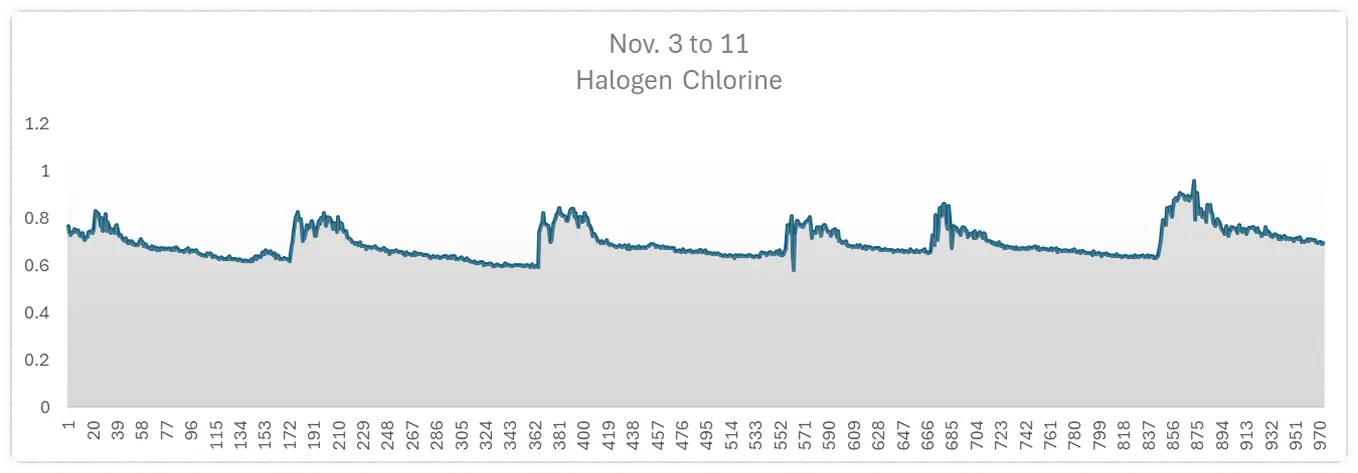

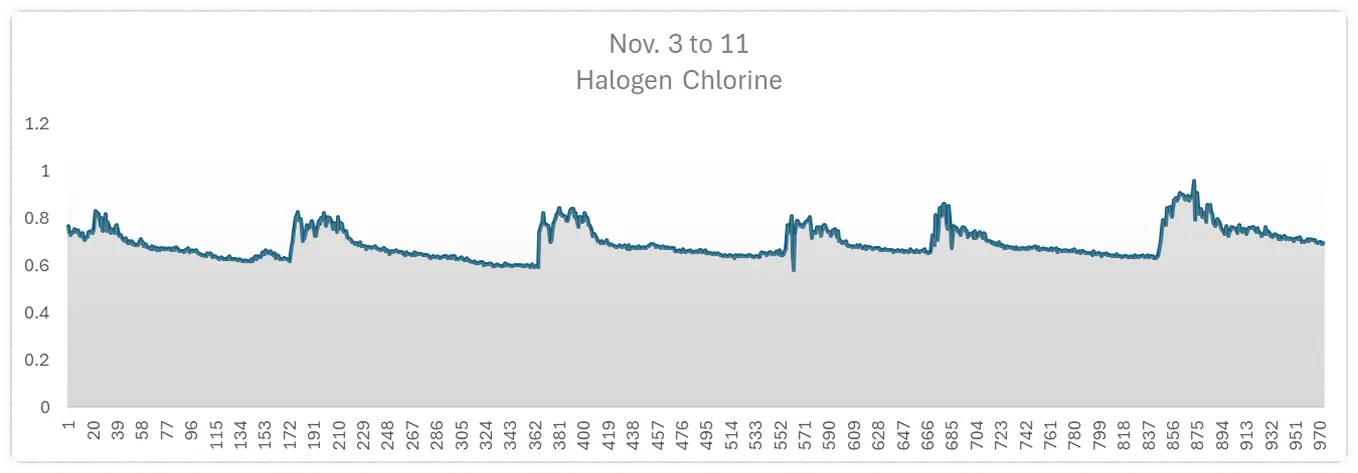

In Figure 4, data from Xylem Data Lake shows the chlorine level dropping as a function of time. The increases are due to periodic flushes which are clearly discerned.

Figure 5: Chlorine levels can be seen dropping with water age, then restored after flushing.

Results

Chlorine levels drop as water ages and increase after flushing, as shown in Figures 4 and 7. The trends are clear. In Figure 8, pH levels rise and then fall post-flushing, with more significant increases during colder months.

For this trial, flushing occurred every night for 6 hours. Depending on triggers, the interval between flushes may be extended. The pH gradually rises with water age and falls after flushing. Less frequent flushing in colder months results in higher pH increases, requiring flushes based on either chlorine or pH levels.

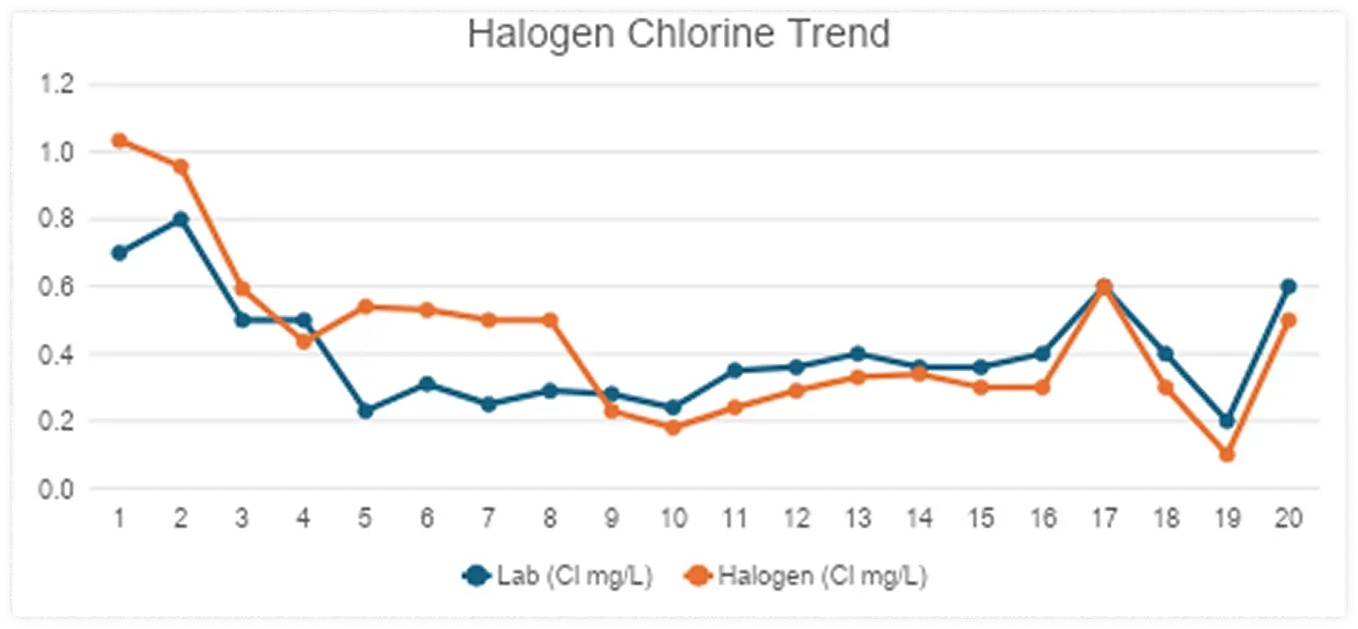

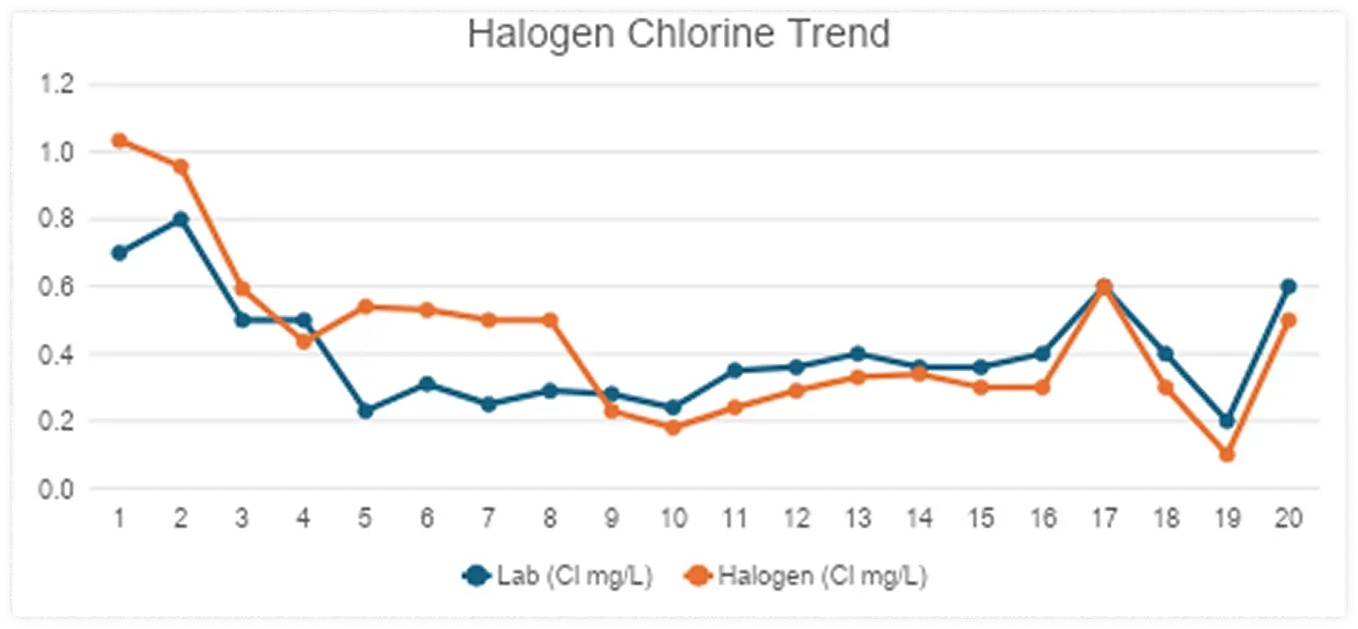

As can be seen in Figure 6, the sensor tracked well with lab samples measured on site with lab instruments for free chlorine and pH. The sensor was not calibrated until September 12, 2024, which accounts for the deviation prior to this date. The sensor tracked well after this date.

Halogen’s MP5-A sensor operated without downtime or maintenance for over 6 months. Out of 2200 measurements, uptime was 99.875% (4 invalid measurements). The Gainesville installation consistently ran at 184 PSI. Based on feedback from the trial, Halogen has introduced a next generation version of the Sensor Interface.

Gen 2 Sensor Interface

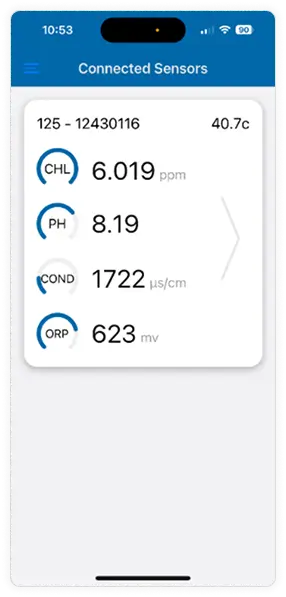

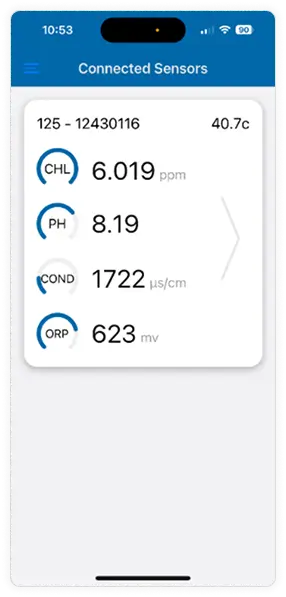

This new version uses a Mobile App to view sensor data when onsite. It can be used with many sizes of rechargeable batteries. As seen in Figure 7, the new design uses two Sensus Smart Gateways, each with independent Gateway triggers. Four measurements are transmitted to the Network. Some of the new features are listed below:

Calibration checks are conducted using a Bluetooth Module and a Mobile app.

An IP68 battery enclosure allows a battery (up to 100 AH) to be installed in a vault, manhole or jumbo meter box. A solar panel connection is included. This enclosure eliminates the need for a separate rain tight enclosure.

Two independent triggers (one from each Gateway) enable Reliable transmission of four sensor measurements.

An additional Sensor Model has been released that adds the measurement of Monochloramine along with Free Chlorine for municipalities that use this as their secondary disinfectant.

Layout of Halogen MP5 Sensor and SENSUS Smart Gateway

The City is satisfied with the results and plans to deploy more sensors. Their experience is detailed in a Water Online Webinar.

- 2 April 2024

Halogen Sensors are ideal for Remote monitoring of water quality.

Water utilities are charged with managing their systems carefully to ensure high water quality for all their end users. Each day utilities take samples of water quality around the system as required by the EPA Safe Drinking Water Act to ensure a variety of parameters such as chlorine, pH, conductivity, and many more, are within required ranges. Water quality is impacted by a number of factors, including system design, secondary disinfectant/ chlorine dosing, consumption, temperature, and more.

One particular concept of high importance for utilities in water quality management is changes in quality between finished water leaving the plant to when it is consumed at service connections. This time difference is known as water age, and higher water age is typically accompanied by poor water quality as secondary disinfectants degrade over time. Even the best system designs can have water age issues, especially at dead end lines or areas where consumption is just not high enough to maintain proper water age. Water utilities often mitigate water age and water quality issues by discharging water from the system in certain areas. This is known as flushing, and it brings fresh water with higher levels of secondary disinfectant to the area. Many utilities conduct this manually, by rolling trucks and sending field operations personnel to open hydrants or blow off points.

Technological advancements offer new approaches not only in the monitoring of water quality in the system but also in the management of water age and flushing. Online monitoring offers a more real time method for tracking changes in water quality at given points, and can help refine and optimize flushing or chlorine dosing in the distribution system. Up to this point, water quality monitoring devices have offered a single parameter, often require power, are deployed in controlled environments such as treatment plants, and often have reagents requiring regular maintenance. New technologies offer multi-parameters measurement approaches, form factors offering direct insertion into the distribution pipes, and battery powered options which makes installation in the distribution system practical and feasible. Additionally, technologies that tie in with Advanced Metering Infrastructure (AMI) systems stand to offer a more holistic approach to water quality management, consolidating information on water usage in the system, quality measurements, flushing operations, and optimization to one central decision point.

Background

The City of Gainesville, Georgia is well known for Lake Lanier and a robust poultry industry. Behind the flourishing city is a water utility that aims to offer the highest level of service to it’s more than 60,000 end customers. Gainesville has a history of leveraging new technology to advance efficieny and ensure high service levels. They have deployed Advanced Meter Infrastructure (AMI) to remotely monitor and read water usage. Their Sensus FlexNet AMI system also helps them track pressure levels across the city, along with water loss.

Gainesville services rural areas located many miles from its treatment plant. In dead-end sections, water age can be problematic and necessitates periodic flushing to restore chlorine and pH levels to acceptable standards. Water age often results in taste and odor complaints. Without an automated flushing system, crews must be dispatched to manually open valves or hydrants to flush the affected piping sections with newly treated water. Manual flushing involves deploying a truck and often leads to inconsistencies due to workload variations, traffic conditions, weather impacts, and available labor.

Leaning into Remote Management

In order to save staff time and improve water quality, Gainesville looked for ways to remotely manage this flushing. Gainesville established remote flushing sites in problematic areas of the network. They are using the Sensus ally water meter which has an integrated remote shut off valve to operate flushing points. The sites are remotely controlled and operate on a timed schedule. For sites requiring higher flow rates, the City developed a novel automated flushing system that uses a Sensus 2” Omni meter attached to a ClaVal on/off valve. An ally meter controlls the valve. This gives the City a method of remotely controlling flushes as well as a record of flushing volume used, which is of particular importance for tracking water usage and loss. Flushing can now be conducted remotely, at lower rates for longer durations, and during off-peak hours such as evening or night.

Gainesville has an initiative to optimize flushing operations to ensure water quality but avoid over-discharge of water and associated non-revenue water. Optimizing flushing by considering consumption in the system, as well as online water quality information. To achieve this, Gainesville looked to integrate water quality sensors at flushing sites measuring chlorine and pH levels. With this addition, it expects to enable on-demand flushing, with a view to replacing the traditional timed flushes.

In a previous demand-based flushing trial, the City used an online DPD instrument for remote chlorine monitoring but found pH levels rose to unacceptable levels in colder months. It concluded that both pH and chlorine must be monitored. Other issues included maintenance every 45 days and limitations due to freezing temperatures.

The City of Gainesville, GA tested new sensor technology from Halogen Systems, Inc. and identified several advantages compared to the previous equipment

Measures both chlorine and pH

Requires no maintenance or calibration for at least six months.

Installed by wet tapping directly into a main and operates in freezing temperatures without needing service.

Enables battery operation, eliminating utility power needs.

Minimizes Non-Revenue Water (NRW) using no waste stream.

Offers sufficient resolution to trigger flushing when chlorine levels drop to 0.35 ppm or when pH rises to 8.9 or higher

These features are expected to lead to significant NRW savings through fewer flushes and reduced truck rolls, as each flush can require around 140,000 gallons depending on the location and no periodic visits to replace reagents are required.

About the Sensor

This new sensor technology incorporates a mechanical and electrochemical self-cleaning system and can be installed directly within a pipe. It is a multiparameter amperometric sensor capable of independently measuring pH, conductivity, ORP, and temperature, regardless of flow and pressure conditions. The self-cleaning feature extends the interval between calibration and maintenance. Installation employs conventional wet tapping equipment in active distribution lines. The service interval is 12 months, with a calibration check required every six months. The sensor operates indefinitely at zero flow and zero chlorine levels without experiencing memory effects common to membrane style sensors.

A new sensor version measures both Free Chlorine and Monochloramine directly in a pipe, without reagents or membranes.

Sensor Installation

The Halogen MP5-A interface supports low power mode for up to six months of battery operation on a 50AH charge. Four 4-20 mA outputs connect to SENSUS Smart Gateways for data transmission to the Xylem Data Lake Dashboard. Data uploads are triggered by the Smart Gateway every 15 minutes.

A vault installation was used due to the depth and size of the pipeline. A jumbo meter box or manhole can be used for 7” and smaller diameter pipe. Sensor installation in an active pipeline uses conventional Wet Tapping Equipment. A Corp Stop valve is installed, then the Halogen Sensor with Remover is attached, and the sensor is inserted into the flow. A sample port enables calibration checks using handheld colorimeters.

Figure 3: Wet tap sensor installation into a 16” main using a Corp Stock valve. Integrated remover assembly enables removal of sensor for service and wet tapping of an active pipeline.

In Figure 4, data from Xylem Data Lake shows the chlorine level dropping as a function of time. The increases are due to periodic flushes which are clearly discerned.

Figure 5: Chlorine levels can be seen dropping with water age, then restored after flushing.

Results

Chlorine levels drop as water ages and increase after flushing, as shown in Figures 4 and 7. The trends are clear. In Figure 8, pH levels rise and then fall post-flushing, with more significant increases during colder months.

For this trial, flushing occurred every night for 6 hours. Depending on triggers, the interval between flushes may be extended. The pH gradually rises with water age and falls after flushing. Less frequent flushing in colder months results in higher pH increases, requiring flushes based on either chlorine or pH levels.

As can be seen in Figure 6, the sensor tracked well with lab samples measured on site with lab instruments for free chlorine and pH. The sensor was not calibrated until September 12, 2024, which accounts for the deviation prior to this date. The sensor tracked well after this date.

Halogen’s MP5-A sensor operated without downtime or maintenance for over 6 months. Out of 2200 measurements, uptime was 99.875% (4 invalid measurements). The Gainesville installation consistently ran at 184 PSI. Based on feedback from the trial, Halogen has introduced a next generation version of the Sensor Interface.

Gen 2 Sensor Interface

This new version uses a Mobile App to view sensor data when onsite. It can be used with many sizes of rechargeable batteries. As seen in Figure 7, the new design uses two Sensus Smart Gateways, each with independent Gateway triggers. Four measurements are transmitted to the Network. Some of the new features are listed below:

Calibration checks are conducted using a Bluetooth Module and a Mobile app.

An IP68 battery enclosure allows a battery (up to 100 AH) to be installed in a vault, manhole or jumbo meter box. A solar panel connection is included. This enclosure eliminates the need for a separate rain tight enclosure.

Two independent triggers (one from each Gateway) enable Reliable transmission of four sensor measurements.

An additional Sensor Model has been released that adds the measurement of Monochloramine along with Free Chlorine for municipalities that use this as their secondary disinfectant.

Layout of Halogen MP5 Sensor and SENSUS Smart Gateway

The City is satisfied with the results and plans to deploy more sensors. Their experience is detailed in a Water Online Webinar.