- Info CenterHalogen MP5 More Accurate Than Hach CL10 - San Jose Water The Report Details Background San Jose Water...Halogen SensiCLĒNE™ The MP5™ was created with stable calibrations and low maintenance as priority requirements. To that end,...

- Industries & ApplicationsMaritime & Aviation

Potable Water

Airport & AirPLane Monitoring

Inflow Source Monitoring

Tanker Monitoring

INDUSTRIALCommercial Buildings

Industrial Processing

Applications - ProductsHalogen SensiCLĒNE™ The MP5™ was created with stable calibrations and...Real Talk about "Continuous Monitoring" Chlorine Analyzer claims Some manufacturers...

- Contact

The Halogen TRO Sensor

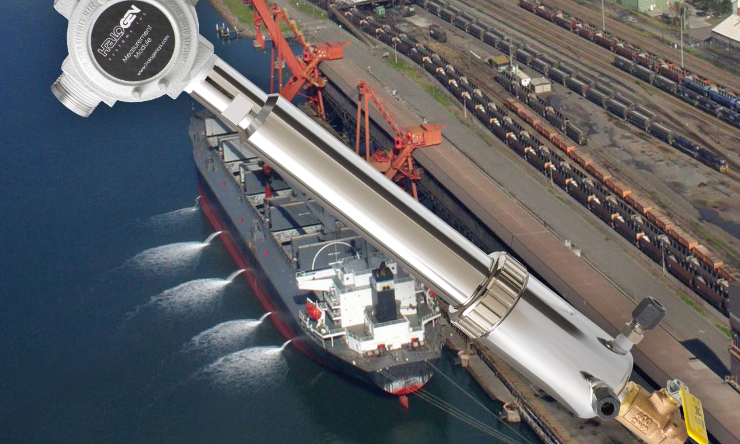

With calibrations that last for months and the ability to be installed directly in the ballast transfer pipes, the Halogen TRO reduces complexity and maintenance while providing flexibility and accuracy.

“We have done extensive testing of this unit and found it to be a robust marine grade field device. We like that the unit mounts right into the ballast water pipe. This avoids sample tubes, sample pumps, and reagents. Looking forward to seeing this on many marine vessels and ballast water treatment systems.” – Kevin Reynolds of OneTank

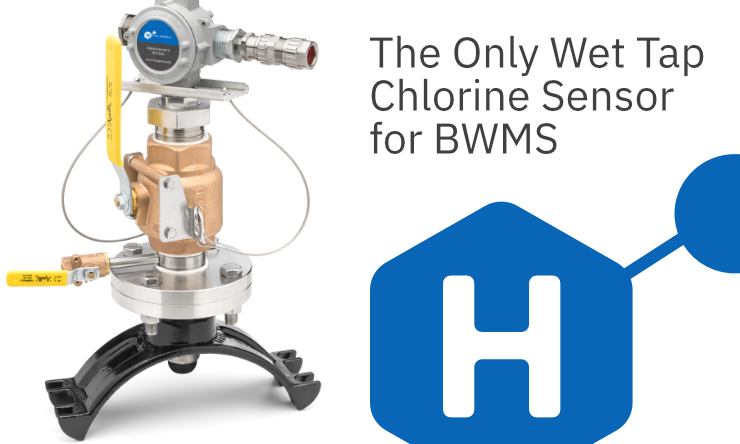

The Only Wet Tap TRO Sensor for BWMS

The Halogen® TRO™ Analyzer installs directly in ballast lines and uses amperometric technology to measure free chlorine plus four additional parameters in one accurate, compact, and reliable unit. The TRO is unaffected by flow or turbidity, automatically compensates for salinity, and retains calibration even in a dry pipe. There is no sensor like the TRO for BWMS applications.

Contact us to start seeing the flexibility gained from using Halogen TRO sensors.

Replace Multiple Sensors with One, While Cutting Membranes, Reagents & Maintenance.

Old-Tech Sinks Time and Money

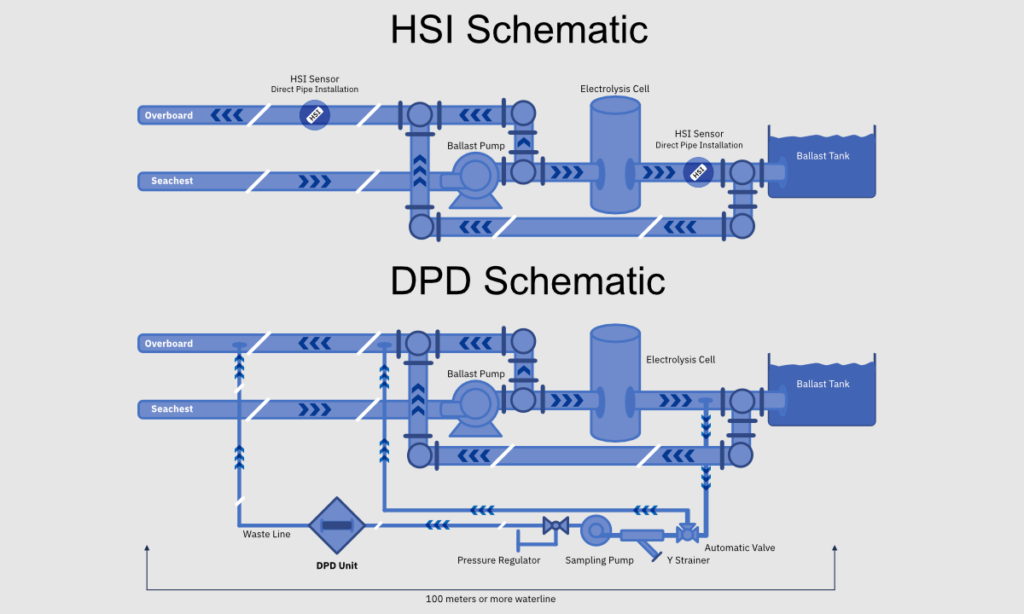

Typical DPD sensors that use membrane and reagent technology drag on the bottom line. The cost of membranes, reagents, and man-hours for maintenance and calibrations are inherent in the old technology. The sooner the old-tech is replaced, the faster the savings are recouped.

Lower BWMS Operating Costs

The TRO sensor arrives factory calibrated, stabilizes in minutes and holds that calibration for months with no membranes or reagents to buy or employ, and very little maintenance at all. Because it can be installed directly in a ballast pipe, there is also no need for flow-control plumbing.

Add Simplicity, Gain Flexibility

With no membranes or reagents to stock or replace, and no need for complicated flow-control piping or even waste lines, Halogen makes BWMS monitoring simple. Owners and operators appreciate the flexible installation options, low maintenance, and calibration stability.

Top Reasons BWMS Engineers choose the Halogen TRO

Certified and Reliable

The Korean Register and DNV have given type approval for the TRO. One version is approved for deployment in explosive environments (IECEx Certificate for Group IIC Gases in Zone 1.)

A Low TCO

After installation, the cost to run Halogen equipment is a fraction of the cost to run an average DPD or sensors that use membranes and reagents. There’s no membrane or reagents to buy, stock, or replace, so there’s no need for constant calibration. Plus there’s no complicated flow-control piping to install or maintain.

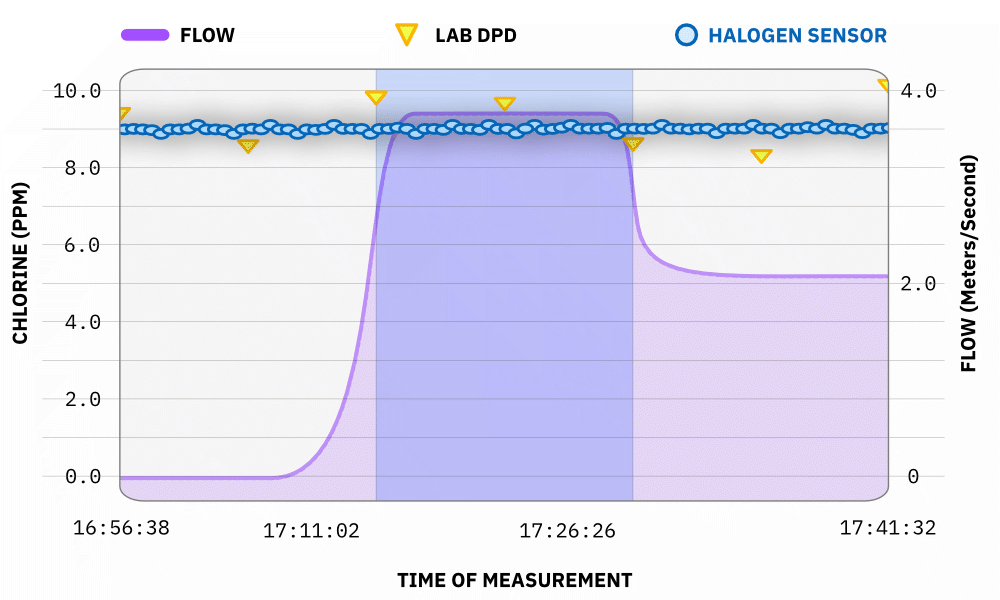

Fast Response Means No Guessing

Typical DPD systems have many meters of flow-control piping between the sensor and the actual ballast pipe. Halogen’s TRO can be installed directly in a ballast pipe and has a cycle time of under 50 seconds. That means the monitoring team can monitor the water in the ballast pipe, not the water in the flow control.

The Halogen TRO™: Simple to Install. Simple to Operate.

Locating the sensor in the ballast pipe makes things simple to install and lowers operating costs. A BWMS based around the TRO does not require installation of sampling pumps or lines, additional automatic valves, waste lines or skid mounting. Operators of BWMS that employ the TRO appreciate the simplicity, longevity and easy maintenance. There are no reagents to stock or replace. Preventative maintenance is eliminated since there is no scheduled maintenance for 24 months, and even calibration checks are based on long intervals.